www.ptreview.co.uk

01

'22

Written on Modified on

A Custom-made Sensor in 3 Phases

Once an Imagineer has identified an opportunity for a ‘smart’ product, the OEM typically wants the development of custom sensors to proceed very rapidly. OEMs from almost every market choose HBK because it’s not just about the sensor. You need a partner with a deep understanding of your application, and HBK experts can actively contribute and advise on fundamental sensor system design.

By listening to our customers, we have learned how to optimize the process of designing, developing and manufacturing custom sensing solutions.

Combine your product knowledge with our product knowledge. We apply design competence with manufacturability in mind. Thanks to our lean processes, global manufacturing and an experienced logistics team, the best possible customized sensor assembly will be ready for your series production, on time and within budget.

1. Design

New custom sensor designs typically begin with an engineering conference. HBK experts work with the OEM's engineering team to clarify the goals and function of the sensor and identify which components can be converted to active measurement. A precise analysis is the foundation for all development work. We propose a test concept, produce control drawings to show how the requirements will be met, deliver costings for prototypes, and discuss the target production price at various volume levels.

2. Prototype

Twenty years of experience with special sensor systems have provided HBK with the experience and deep practical insights into developing customer-specific strain gauges. Rapid prototyping techniques enable our team to build and deliver functional test samples within a few weeks. Before we ship them, it's imperative to talk about how to mount the samples and test them. After this discussion, we can provide test protocols, fixtures, and test amplifiers to ensure the best test results.

3. Production

With testing successfully concluded, the prototype sensor transitions seamlessly into series production - often, within six months of the initial Engineer-to-Engineer discussion. In HBK factories, lean manufacturing techniques and automation combine to ensure smooth production processes with high-quality standards. Our focus on our own manufacturing facilities and processes ensures that OEMs receive quality manufacturing plus scalability to match the growth in demand for your product.

1. The Design Phase

A dedicated group of engineers will work with you to clarify your needs and the desired function of the sensor, including which components should be considered for measurements. Here HBK reviews the possibility of turning existing components into active sensors.

1 - Enquiry

Your enquiry for a customized sensor is our starting signal. Our dedicated OEM engineering team is standing by in Marlborough, Massachusetts, ready to deliver professional support. In an email or quick conversation, we can learn about your objectives and set a date for the engineering discussion.

2 - The Engineer-to-Engineer discussion

At this meeting, we learn about your requirements in detail and what you want us to deliver. We will listen to your needs, discuss the design options and brainstorm suitable sensing solutions. At the HBK competency center we prepare the solution that will deliver the quality of data that you need.

The complete assembly can include a strain gauge, the sensor body (an existing part, or a new part), the cabling, electronics and mounting components.

3 - Exchange of drawings

After exchanging technical drawings, we perform finite-element analysis (FEA) to determine whether we can turn your part into an active sensor or have enough space to add a sensor. The combination of FEA, together with our extensive experience of manufacturing in volume, will provide you with the best solution.

4- Review

With the preliminary design accepted, HBK proposes a solution that includes: product and performance requirements; an initial risk analysis; the development plan for your sensor; test plan and protocols. As we move into the prototype phase, we have a joint vision of how the solution will look and perform.

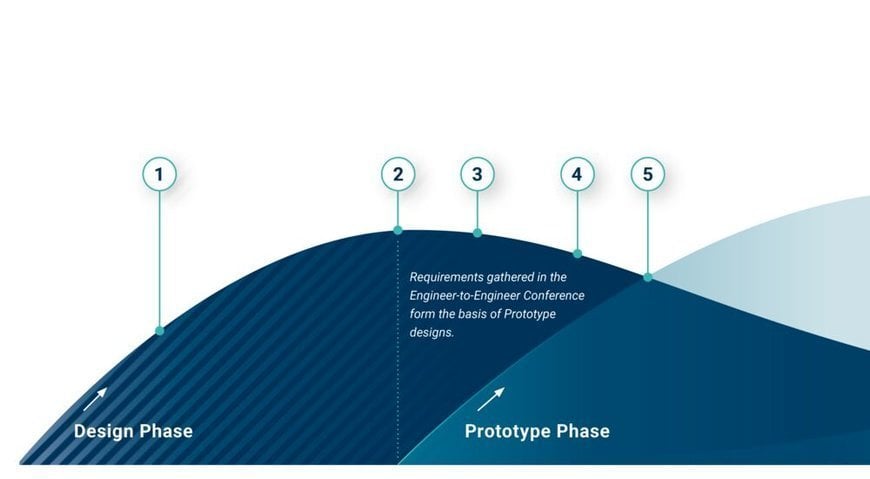

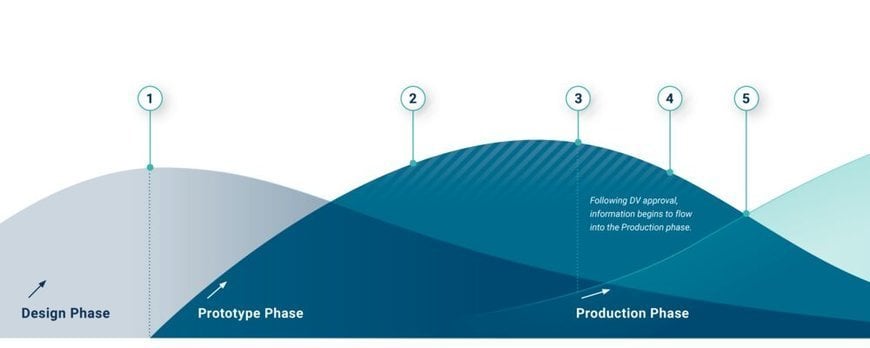

2. The Prototype Phase

Rapid prototyping techniques enable the HBK team to build functional test samples within a few weeks. Before we ship them, it’s imperative to talk about how to mount the samples and test them. After this discussion, we can provide test protocols, fixtures, and test amplifiers to ensure the best test results. We will provide control drawings, a partner-pricing cost for prototypes, and a price estimate for series production.

1 - Requirements

The product requirements, discussed in the Engineer-to-Engineer Conference form the foundations of the Prototype phase.

2 - Virtual model – First Prototype

The HBK design team uses techniques such as rough CAD, rapid prototyping, FEA and 3D modelling to develop samples. In partnership with you, we identify other components of the bill of materials (BOM) that can include cables or a sub-assembly that contains our HBK electronics. The milestones in this stage are the engineering confidence test; test reviews; actual testing; and proof-of-concept (POC) approval.

3 - Physical samples phase

The key issues to discuss and resolve in this phase include the successful testing of the sensor assembly and finalization of drawings. We also finalize validation and testing; whether tests under any specific environmental or operating conditions or loads are appropriate; which ‘special’ aspects to test (such as ingress protection, material coatings, sealing issues, etc.). We also identify the steps in the manufacturing process and finalize DFMA issues. The milestones for this stage are Design Validation (DV) and customer approval.

4 - Results of first Prototype Tests – test protocols established

Defining the test protocols allows us to focus on the implications of the data, rather than how the data is collected. Jointly agreeing to test fixtures and data acquisition equipment ensures that both our companies have consistent methodologies that deliver accurate readings. By aligning the test parameters upfront, we create Quality-by-Design. At this point, the sensor assembly starts to become a key part of our customer’s ‘smart product’.

5 - Production intent audit

All HBK factories have ISO accreditation, and our experts are comfortable with audits. The production intent audit is particularly important, as it enables auditors to see where and how their product will be built in volume. As your strategic partner, HBK welcomes this kind of cross-department effort.

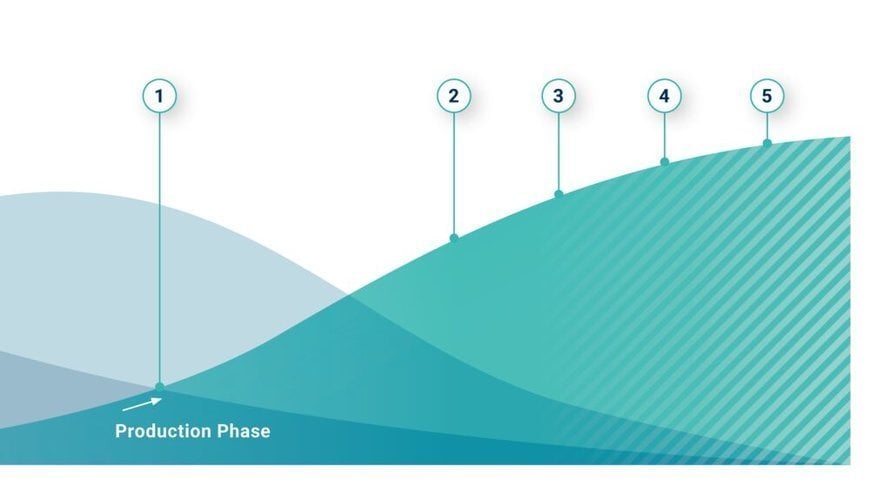

3. The Series Production Phase

In our experience, OEM sensor assemblies often go into volume production within six months of the initial Engineer-to-Engineer discussion. In HBK factories, lean manufacturing techniques and automation combine to ensure smooth production processes with high-quality standards. HBK’s focus on its own manufacturing facilities and processes ensures that OEMs get quality manufacturing plus scalable volumes. As your new ‘intelligent’ product gains traction in the market, you can scale sensor assembly orders to match the growth in demand. HBK will ramp up production to keep pace as needed.

1 - Quality – A step ahead

Throughout the development process, we have been designing for quality. In this stage, we formalize the data collection, inspection points and analytics to ensure the highest quality possible. We provide detailed control plans and capabilities studies. We have extensive experience with the Production Part Approval Process (PPAP) - as do our suppliers. We provide samples with supporting data showing design, specifications, and our process control for volume production. HBK is proud of its history of leading quality standards. In August 1986, HBM was the first German company to be certified to ISO 9001 and is an accredited Calibration Laboratory, ISO 17025: D-K-12029. We also maintain compliance on numerous items such as RoHs 3 and more.

2 - Test processes – How you test is how we test

In addition to producing high-volume sensor assemblies with the fewest rejects, we work closely with our clients to develop application test protocols. When producing an assembly that will be integrated into complex customer parts, it is best to clearly understand how the assembly is integrated, mounted, and tested to uncover any errors that may occur in the handling and testing of the parts. HBK manufactures high-quality laboratory equipment and software to assist this process and has specialized equipment in-house (such as autoclave machines) that can be included for in-line testing.

3 - Lean Manufacturing

All of our facilities are fully committed to lean manufacturing to minimize waste and continually improve operational efficiencies. Kaizen events are held often and Gemba walks are numerous - both are constants in our calendars. We are committed to producing to the highest standards and our ambition and goal are always “Zero Defects”.

4 - Automation

With the design and quality systems defined, HBK automation experts will optimize production with automation as appropriate. From gage placement to printed circuit board (PCB) assembly, automation allows for consistent quality and optimized value. Having the best technology available, HBK has all types of modern equipment including automation, wire bonding, CNC, 3D printing, autoclave testing and much more. Since we own the largest strain gauge production facility in the world, we have both the ability and the experience necessary to meet demand.

5 - Logistics and Agile Supply Chain Management

Complex supply chains require detailed attention to packaging and logistics to ensure timely deliveries. Using our SAP enterprise resource planning system, the logistics group works closely with freight forwarders to ensure around-the-clock visibility of materials. Our three production facilities, strategically located in Europe, Asia and the United States, minimize logistics disruption and risk for our customers. Direct access to our logistics team means we can respond quickly to any changes in your forecasts or needs.

www.hbkworld.com