www.ptreview.co.uk

13

'22

Written on Modified on

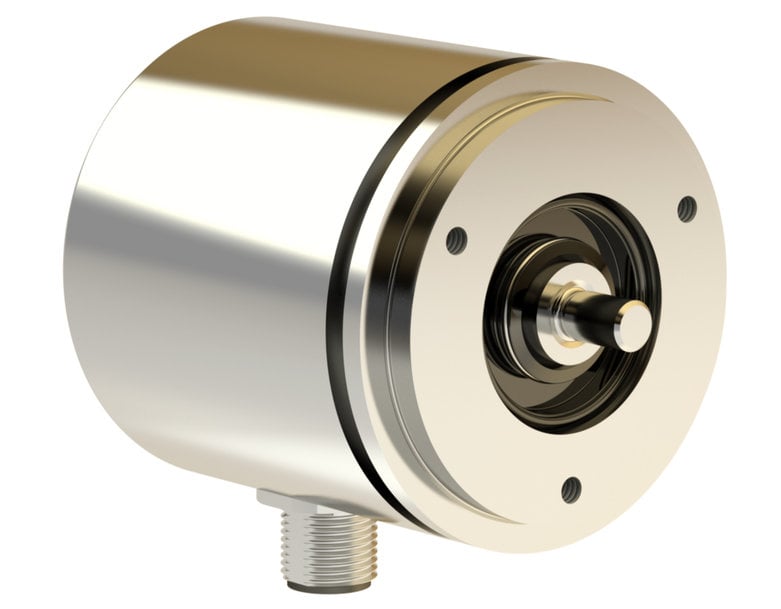

Aiming high: the four-million-step rotary encoder

Sometimes it just has to be more. In this case, TWK's newly developed ABN encoder model has a resolution that divides the full circle of 360° into over 4 million steps. To be precise, in 222 steps - that's a resolution of 22 bits. High accuracy is equally important. This is impressive with better than ±10 arcsec. That is less than ±0.003°. Precise measurements of positions and speeds up to 10,000 rpm are thus possible. The ABN will be available from September 2022.

These values are achieved by scanning a high-precision optical code disc. Equipped with the CANopen or CANopen Safety interface, the encoder, which is designed to be functionally safe, can also be used for safety-relevant applications. The requirements for SIL2 level according to IEC 61508 are fulfilled. Internal monitoring functions ensure that in the event of an error, a safe state is assumed and an error message is sent to the control system. The measuring range of the single-turn encoder ABN is 1 revolution. The multiturn counterpart ARN is in the planning stage, whereby up to 24 bit revolutions are reliably detected. That is a measuring range of almost 17 million revolutions. Due to the scanning principle with code disc, versions with through hollow shaft are possible.

Mechanically, versatile features are also available for the ABN/ARN model: different housing materials - from seawater-resistant aluminium to food-compatible stainless steel. A range of different flange and shaft designs as well as M12 connectors or cable connections are part of the programme. With the shaft version for connecting the backlash-free TWK ZRS target wheel, the smallest movements of an internal or external ring gear can be reliably detected and transmitted to the control system.

Special software for slewing ring applications, which calibrates the position signal directly to the slewing ring, ensures that the position signal has a zero transition at a full revolution of the slewing ring, so that one always knows in which direction, for example, the jib of a mobile crane is pointing. The position signal goes from 0 to 360° with parameterisable transmission ratio and resolution. This output code continues to work reliably even if the measuring range of the encoder has been traversed and is rotated further.

The ABN encoder thus joins the portfolio of safety sensors that includes many different sensor types and interfaces. From inclination and vibration sensors to cam switches, in which safety switching contacts are integrated in an encoder that can be switched into a safety chain and safely interrupt it when position or speed limits are exceeded. The encoders in particular are available from small and space-saving to heavy-duty, with protection classes up to IP69K and also as fully redundant versions that contain two autonomous measuring systems that also monitor each other internally.

www.twk.com