www.ptreview.co.uk

04

'22

Written on Modified on

New solutions for new challenges

Automation without risk – this is what beginners and experts in automation both want. At automatica, the leading trade show for intelligent automation and robotics, application expert SCHUNK will be showing new ways as well as clever digital services that enable customers to master their tasks and design production processes flexibly and efficiently.

Automation and robotics are developing rapidly. Industrial and service robotics are achieving high growth rates – with an upward trend. This is because new fields of application, ease of implementation and operation, and the need for reliable and individualized processes are pushing development forward. With enthusiasm and innovative solutions, SCHUNK, a family-owned company based in Lauffen, Germany, is heading towards the future together with its customers and partners. The collective vision of automated, autonomous production is increasingly becoming reality. At automatica in Munich from June 21 to 24, 2022, SCHUNK will be presenting examples of solutions for the wide range of automated manufacturing in most different fields of application through personal dialog with experts: from life sciences to eMobility – from handling to robot-assisted machining.

Cleverly bundled

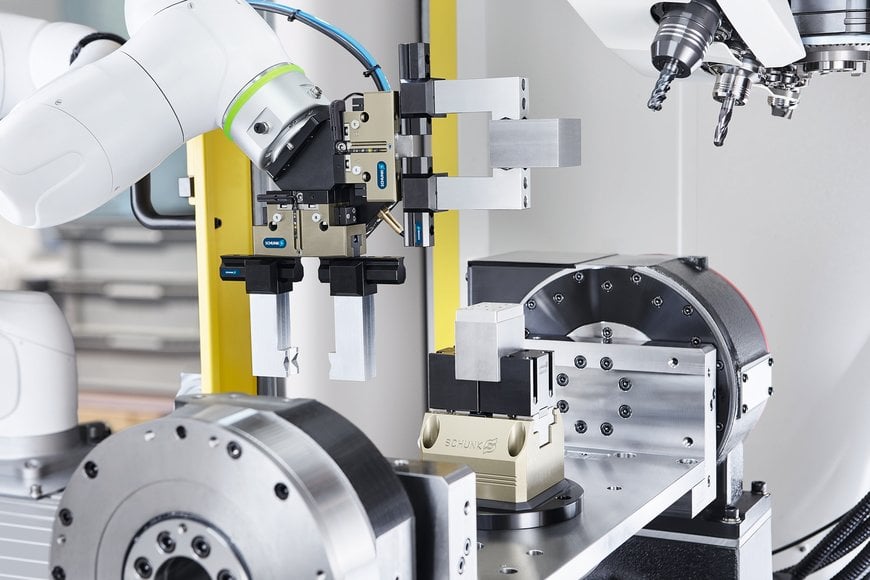

There is still a lot of hidden efficiency potential, especially in metalworking manufacturing environments. The new MTB application kits from SCHUNK provide a convenient introduction to automated machine loading with cobots. The kits include universal grippers and clamping vises that are already preconfigured for use in metal-cutting machining. Suitable robot-specific connection kits enable straightforward commissioning, save time during planning, and speed up machine loading and unloading up to 50 percent. The user-friendly application kits are ideally suited for challenging use in machine tools due to special features such as the sealed valve box or an integrated blow-off nozzle for dirt and chips.

MTB application kits enable entry into the partial automation of machine loading and unloading with cobots. Image: SCHUNK

New members of the pneumatics family

The classics in automation, the pneumatic grippers, have also seen some changes: These proven all-rounders remain indispensable in most sectors of industry due to their reliability and wide range of variants. The competence leader for gripping systems and automation solutions is setting new standards here for the flexible handling scenarios of tomorrow with enhanced technologies such as integrated process monitoring, increased safety, or individualization options. In Munich, SCHUNK is presenting new members of its pneumatic gripper family, which impress with their unrivaled features. SCHUNK is also expanding its digital services and taking the next step towards individualization with freely configurable products. It began with the FGR finger configurator introduced in spring of 2022. This smart tool can be used to plan and order customized gripper fingers with just a few clicks. As a real surprise, SCHUNK will be presenting a new configurable, pneumatic long-stroke gripper at automatica.

Users can configure customized FGR gripper fingers via a web tool and adapt them individually to the workpiece. Image: SCHUNK

Sustainable and easy to integrate

In times when the energy balance is playing an increasingly important role, technological approaches that enable energy-efficient production are in demand. With its new magnetic and adhesive grippers SCHUNK is making a contribution to energy-saving handling. One example is the EMH electro permanent-magnetic gripper, which SCHUNK is presenting with new variants at automatica. It combines the strengths of magnetic technology with the advantages of 24-volt technology. These grippers are reliable tools when it comes to gripping ferromagnetic small components. Another highlight will undoubtedly be the sustainable gripping technology of ADHESO, with which SCHUNK is conquering new fields of application. Inspired by nature, the gripper overcomes technical limits in the handling process and enables gentle, residue-free gripping without the need of external energy – for example, for battery and fuel cell production, in the medical and pharmaceutical industries, or in the electrical industry.

With sustainable ADHESO gripping technology, gentle, residue-free gripping is possible without any external energy. Image: SCHUNK

An outlook into the future

Production is becoming increasingly autonomous. Handling components are no longer simple products, but intelligent solutions for robotic tasks. Equipped with cameras and sensors, they provide important process knowledge for intelligent and autonomous services of the future. Intelligent gripping, intuitive operation, self-learning devices or autonomous milling are examples of these endeavors that are leading to new perspectives in robotics and automation. SCHUNK speaker Dr. Martin May, Director of the Innovation Center, will provide new ideas and a glimpse into the autonomous future at the automatica Forum on June 23, 2022. SCHUNK visitors can get their free entry ticket code at schunk.com/automatica.

www.schunk.com