www.ptreview.co.uk

23

'21

Written on Modified on

Desktop Metal and the Korea Institute of Industrial Technology Partner to Accelerate the Adoption of Metal Binder Jetting for SMEs in South Korea

Installations of Desktop Metal’s Production System and Shop System Platforms Will Catalyze the Innovation, Development and Commercialization of AM Technologies in South Korea.

Desktop Metal (NYSE:DM) and the Korea Institute of Industrial Technology (KITECH) today announced a partnership to accelerate the industrialization and adoption of additive manufacturing (AM) in South Korea starting with the installations of the Desktop Metal Shop System™ and Production System™ P-1 platforms.

KITECH is a leading research institute that facilitates the development of manufacturing technologies for companies across South Korea, with a focus on small and medium enterprises (SMEs). The installation of Desktop Metal’s state-of-the-art binder jet solutions will enable KITECH to help drive adoption of these production-focused technologies with SMEs to address use cases in automotive, consumer electronics, heavy industry, and oil & gas market segments. KITECH plans to leverage Desktop Metal’s solutions to manufacture components at industrial scale volumes and develop new materials for a variety of AM applications.

“We at KITECH are very excited to partner with Desktop Metal on the installation of its industry-leading metal AM solutions,” said Dr. Chung-Soo Kim, Project Manager and Sr. Researcher at the 3D Printing Manufacturing Process Center, KITECH. “Metal binder jetting is disruptive to most other metal AM technologies because of its ability to produce components at unprecedented speeds and low costs. The adoption of binder jetting will change the development environment in the additive manufacturing industry in South Korea.”

“With Desktop Metal’s solutions, we can extend our capabilities beyond the limitations of laser-based additive manufacturing solutions and make significant contributions to the future of key South Korean industries, including automotive, shipment building, oil & gas, and consumer electronics,” said Dr. Dong-Hyun Kim, Head and Principal Researcher at the 3D Printing Manufacturing Process Center, KITECH.

“Metal binder jetting is ripe for adoption in Asia-Pacific, and we are honored to partner with KITECH to further scale the technology in South Korea," said Ric Fulop, Founder and CEO of Desktop Metal. “With our shared vision, the installation of these binder jet solutions will serve as a catalyst for innovation, development and commercialization of AM 2.0 technologies in the region, and accelerate the transformation of the manufacturing industry worldwide.”

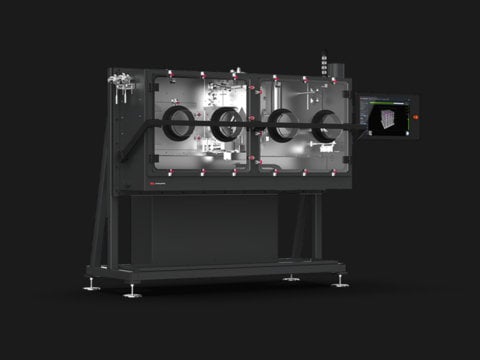

Created by the inventors of binder jetting and single-pass inkjet technology, the Production System is an industrial manufacturing platform powered by Desktop Metal’s patent pending Single Pass Jetting™ (SPJ) technology. It is designed to achieve speeds up to 100 times those of legacy powder bed fusion additive manufacturing technologies and enable production quantities of up to millions of parts per year at costs competitive with conventional mass production techniques. The platform consists of two printer models: the P-1, a solution for process development and serial production applications, and the P-50, a large form factor mass production solution for end-use parts. The Production System combines Desktop Metal engineered binders with an open material platform, allowing customers to produce high-performance parts using the same low-cost metal powders used in the metal injection molding industry. An inert processing environment enables compatibility with a variety of materials, including high-performance alloys and even reactive metal powders, such as aluminum and titanium.

Featuring the most advanced single-pass print engine in the binder jetting market, the Shop System offers a turnkey solution for producing complex, end-use metal parts in a fraction of the time and cost of conventional manufacturing and comparably priced legacy AM technologies. The system includes all of the equipment machine shops need to begin binder jetting - from printing through sintering - and is designed to scale throughput with a range of build volume configurations. In addition, Desktop Metal software for build preparation and sintering simulation, in combination with metal powders and process parameters optimized to deliver exceptional part quality and repeatability, make it easy for businesses to get up and running with binder jetting in days instead of weeks or months.

www.desktopmetal.com