www.ptreview.co.uk

14

'21

Written on Modified on

Platinum temperature sensors: differences and uses

The temperature is a unit of measurement for the thermal state of a material or medium. The most widely used measurement method for determining the physical variable temperature is measurement using a resistance thermometer (temperature probe).

With such a resistance thermometer, the electrical resistance of the sensor changes as a function of the temperature. A resistance thermometer consists of a sensor and other components, such as connecting elements and connecting cables (for more detailed information, read the report on resistance thermometers).

A widespread and very precise type of sensor element for temperature measurement is the platinum sensor.

Platinum (Pt) sensors belong to the group of RTD sensors. RTD stands for „Resistance Temperature Detector“ and refers to sensors in which the resistance is dependent on the temperature. The temperature can thus be determined by measuring the sensor resistance.

Platinum sensors are available in two different designs: platinum thin-film sensors and wire-wound platinum sensors. Platinum thin-film technology is widespread in Pt sensor elements. Thin-film technology is a micro-structured combination of layers made of ceramic, metal and glass. In addition to the widespread layer technology, some Pt sensor elements also consist of a fine platinum wire winding. This wire winding is applied to a base body, which is either made of glass or ceramic. These sensors are called wire-wound platinum sensors.

Compared to other RTDs, the platinum material in the Pt sensors provides a resistance that is considered to be very long-term stable. Another advantage over other RTD sensors is the electrical resistance of the platinum sensors, which changes almost linearly with temperature over a wide temperature range. As the temperature rises, so does the resistance. This enables measurements over wide temperature ranges. A resistance value is supplied by measuring the voltage drop, which is then used to calculate the absolute temperature.

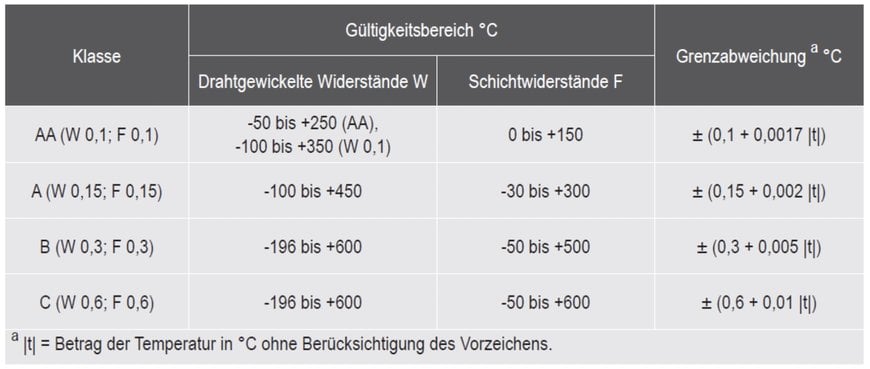

All platinum temperature sensors are standardized according to DIN EN 60751 for the temperature range -200…+850 °C. Regarding the temperature, however, it should be noted that the accuracy classes only apply to certain temperature ranges (see table). This standard specifies when which sensor must have which accuracy class in order to be allowed to be designated as Pt100 or Pt1000, for example. In the case of Platinum sensors that do not conform to the standard, a lable must therefore be added.

Accuracy classes according to DIN EN 60751:

With regard to the accuracy classes, it must be noted that DIN EN 60751 was adapted in 2008. Since then, the standard has differentiated between sensor elements (the actual Pt100, Pt1000, etc. sensors) and resistance thermometers (probes). The standard also differentiates between wire-wound and film resistors.

In addition, B+B also offers the accuracy class 1/10 DIN up to 350 °C. This is a non-standardized class. The deviation is calculated using the following formula:

± (0,03 + 0,0005 x |T|) °C

What does the term Pt100 or Pt1000 mean?

The most common Pt sensors are the Pt100 and the Pt1000. The number after the designation „Pt“ stands for the resistance at a temperature of 0 °C. Thus, a Pt100 sensor has a nominal resistance of 100 Ω at a temperature of 0 °C. In conclusion, the Pt1000 sensor has a nominal resistance of 1000 Ω at 0 °C.

But what does that mean? Here is an example to illustrate:

Pt100 has a nominal resistance of 103,9 Ω at 10 °C (the resistance increases with temperature, i.e. from 0 °C to 10 °C, resistance increase of 3,9 Ω)

Pt1000 has a nominal resistance of 1039 Ω at 10 °C (the resistance increases with temperature, i.e. from 0 °C to 10 °C, resistance increase of 39 Ω)

Of course, in addition to Pt100 and Pt1000 sensors, there are also Pt200, Pt500, Pt10000, etc. sensors where the number also stands for the resistance at 0 °C. The choice of which Pt sensor is used mostly depends on the input of the control unit and the accuracy. For example, it makes sense to use a Pt1000 sensor with a 2-wire circuit, since the line resistance there has a relatively minor influence on the measurement result than with a Pt100. The reason is that the base resistance of a Pt1000 sensor is 10 times higher than that of a Pt100 sensor. You will find detailed explanations of the different conductor technologies used in temperature sensors in the next application report from B+B.

www.bb-sensors.com