A Green Transition in Industry: Creating a 3D printer using recycled material

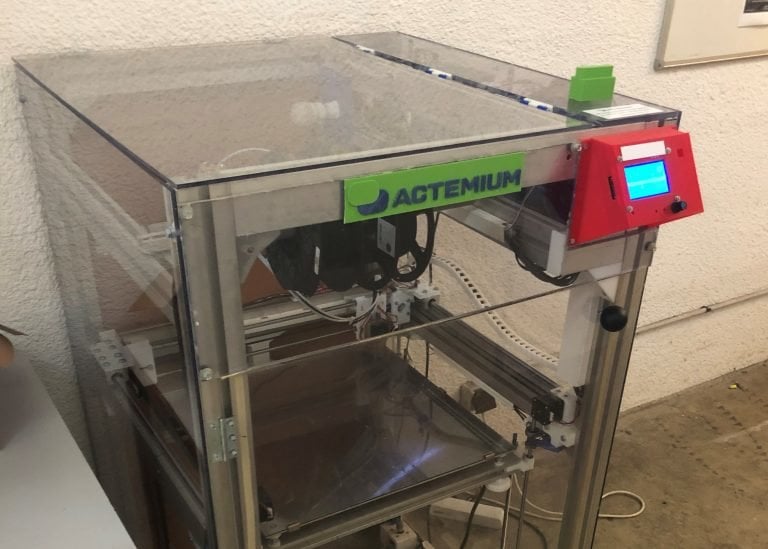

Maintainers are often faced with obsolete equipment that is no longer manufactured. To fight against obsolescence, Actemium Adour Pyrénées manufactured a 3D printer, by using 80% of recycled materials, to create custom parts to replace broken pieces for industrial clients.

The frame, casing, tray, power supply, cable support, etc. are made from materials that were intended for the recycling center. The connecting pieces were made using another 3D printer based on a biodegradable polymer from corn, beets, rice and cassava. This self-built solution turned out to be a real challenge in terms of design because it was necessary to adapt to the characteristics of the materials recovered. On the other hand, this will significantly reduce manufacturing costs.

Since January 2019, the printer has produced a panel of parts based on technical and societal needs:

- HTB disconnector locking handles

- HT System Interlock Key Handles

- Electrical connectors

- Protective cover for compressor motor fan

- Various parts to repair the household appliances of employees

- For COVID, the printer was adapted to produce: Mask fasteners, Visor headband, Nose clip, Contactless door opening keys