www.ptreview.co.uk

15

'21

Written on Modified on

AUTOMATION IN LASER MARKING IS MORE THAN ROBOTICS

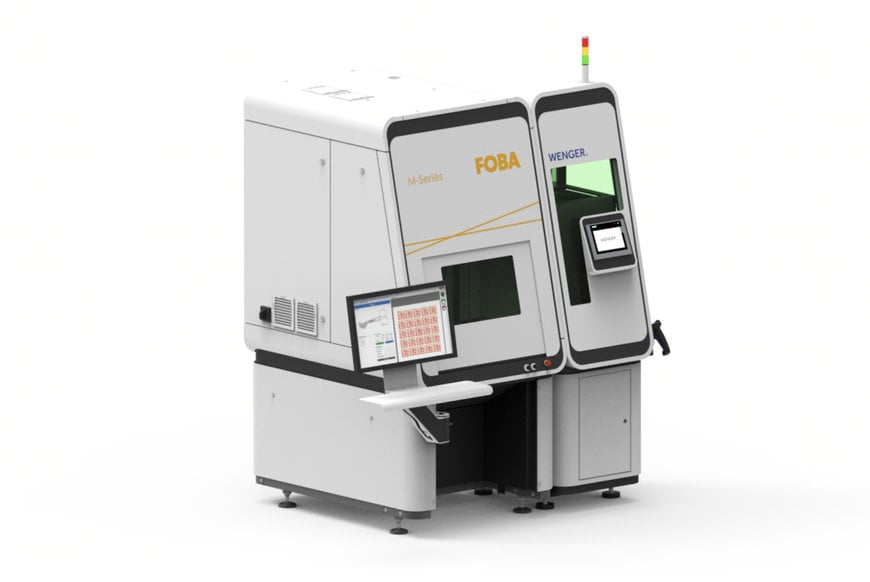

Customized automation solutions from visual process control to robotic parts handling: Automation of laser marking can help manage increasing marking requirements and save costs in the production process. Especially in the context of increasing traceability marking regulations, the direct part marking is on the rise. Therefore, FOBA, in cooperation with automation experts, offers technical solutions that make the marking process more efficient for industrial customers. How this is implemented differs individually.

Automation processes related to laser marking include the loading and unloading of a marking station from the outside, pick and place operations within a closed marking unit, but also stacking, sorting or a subsequent packaging and cleaning. A distinction is made between semi-automated and fully automated systems, which differ in the degree of human interaction required.

In addition to the automation of parts handling, the automation of the marking process itself also plays an important role. This primarily involves the exact positioning of the laser mark at the intended position on the product with the help of an integrated camera and corresponding software. The intention is not only to minimize human interaction, but also to make the process repeatable with consistent accuracy.

"As a pioneer in the field of camera-based laser marking, FOBA has already enabled a certain degree of automation of the marking process for many years," says Markus Vetter, FOBA product manager. This primarily concerns mark alignment by automated optical inspection, enabling the exact placement of the mark in relation to the component, as well as software-controlled quality checks from the beginning to the end of the marking process.

Process control through camera and software features

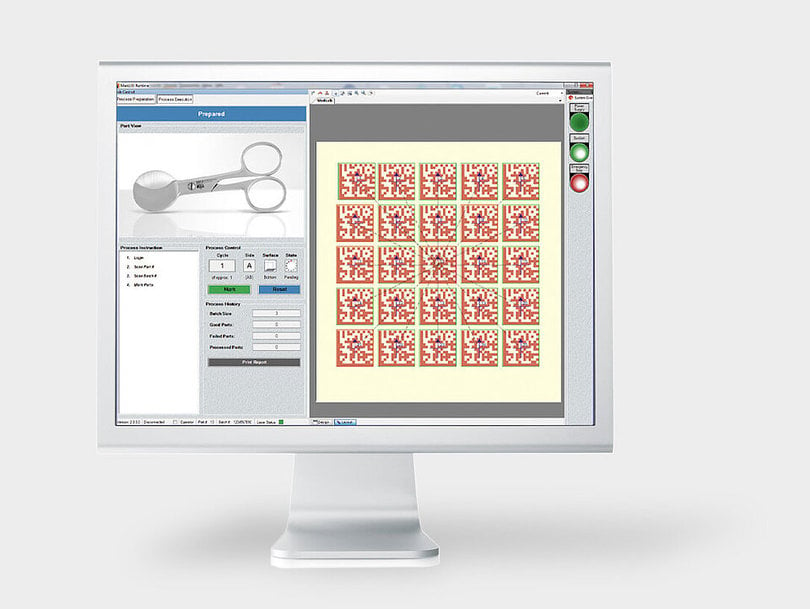

The integration of the camera directly into the marking head ensures distortion-free imaging, the prerequisite for precise marking through automatic positioning and orientation of the marking contents. At the same time, the software performs visual inspection of all parts prior to marking to prevent false marking, as well as a downstream readback of the marked codes for quality and content control.

Certain software functions such as Mosaic, part of the FOBA MarkUS marking software, are capable of accurately marking a product located anywhere in the marking field. This not only saves time and effort in manually aligning the product to the laser, but also the considerable cost of manufacturing and equipping the respective product holders (fixtures).

In medical device manufacturing for instance, there is a great variety, both in terms of the type and shape of the products, their material or also the production quantities with often small batch sizes. Consequently, the requirements for marking and the degree of automation of the marking process also vary. "We always see our task first in providing profound advice and analysis of our customer’s requirements. If we are then unable to offer a suitable solution with our own technical department, we recommend the appropriate partner with the necessary expertise," explains Son Tran, FOBA Sales Manager Europe. "By expanding our portfolio to include semi-automated loading and unloading processes, FOBA is further meeting current customer needs for automation," adds Markus Vetter, explaining FOBA's cooperation with robot manufacturers and automation partners.

A prerequisite for the interaction of laser marking system and robot or automation system is a technically smooth interface connection of both systems. "Our laser marking systems contain sophisticated interfaces and can be integrated very well into automation units or connected to robots or other systems. This functionality is based on our experience with a wide variety of production environments," explains Son Tran.

"In addition, at FOBA, all elements of the marking process, including the camera and illumination, are controlled by a single software. This means that our customers do not operate their process with different programs, which is an advantage in many cases," FOBA’s sales manager adds. Furthermore, the integrated camera also reduces the effort of validating the marking process, as no additional validation is required for a separate camera software. FOBA considers this to be a great advantage in the required medical device qualification process.

Semi-automated loading and unloading

The following examples from industrial practice show that there are solutions for a wide variety of marking requirements. "The cooperation partners named here to develop automation solutions together with FOBA are representative of a range of global partnerships," explains Product Manager Markus Vetter.

FOBA shows what a semi-automated marking solution might look like in the case of a laser marking service provider for medical device manufacturers: an industrial robot removes a tray containing several parts to be marked from a carrier cart and places it in a FOBA M2000-P marking station. The spacious marking field as well as the camera-assisted mark alignment enable the subsequent marking of several parts in one pass.

In the laser, the integrated camera takes over the automated inspection of all parts, the alignment of the position of the marking and the exact marking. The marking software can identify the shape, size, possible defects or incorrect assignments and, if necessary, distinguish individual parts to be excluded from the marking. After marking, the marking station opens, the robot removes the tray again and reassigns it to the original insertion location in the service cart.

Marking service provider add'n solutions from Tuttlingen appreciates the advantage of this automation solution, developed by industrial robot system provider fruitcore robotics: the option to produce around the clock if required, and to do so with a high degree of accuracy and free of scrap. In addition, the employees' working time does not have to be tied up for simple loading activities, but they can concentrate more on qualified tasks.

Docking modules for highly flexible part processing

Other particularly flexible and fully automated marking solutions are based on a docking module that is connected directly to the FOBA M-Series marking workstations (M2000 or M3000). The docked automation cell is adapted to the FOBA marking workstations in terms of format and appearance and can be loaded with up to 20 pallets, which are individually drawn into the marking unit via linear kinematics.

"The advantages of these infeed systems are their relatively small footprint and ease of operation due to the elimination of additional programming work for an external robot gripper arm. Instead, a tablet infeed is fully integrated into the loading unit," explains Markus Vetter. In addition, these "WeStore" modular systems from Swiss automation specialist Wenger could also be operated manually in the classic way via the front door of the M-Series marking station, for example for manual processing of small batches.

Practical experience shows, however, that geometrically complex workpieces often require very individual part marking approaches. For such cases, Wenger equips the loading module with a 6-axis robot and optionally with an automatic gripper change, which is used to mark different workpieces directly one after the other. In addition, there is the option of combining it with FOBA's rotary unit, making highly customized processing possible, according to FOBA’s product manager. "The associated software has been specially developed for the medical sector, making it easy to connect to existing SAP or ERP systems and thus also validating the entire marking process."

Stack loading and special software solutions by FOBA

FOBA also offers special machines developed inhouse for automated stack tray loading: "For our core market of plastic paint removal, so-called day-night marking, we have developed a solution for parts processed continuously on carrier trays," explains product manager Markus Vetter. This involves the production of small parts that are previously provided in larger quantities on stackable carrier trays. Autonomous gripping and loading systems supply the marking system with large volumes of parts, enabling several hours of operator-free production.

When it comes to software, marking system provider FOBA tries to enable individual solutions in each case. "Depending on customer requirements, we are also able to offer special software, for example, user guidance for very specific applications," says Son Tran, emphasizing how important competent customer advice therefore is.

Optional equipment: Rotation unit, motorized axes or rotary table

There are applications, especially small batch sizes or parts that are particularly delicate or demanding in terms of marking, when a robotic solution does not make sense and humans cannot be replaced. But even without robotics, a marking process can be streamlined decisively, because there are various optional extras that make the use of a marking system more flexible and efficient.

For example, a rotary unit can greatly simplify the marking of cylindrical parts. This has been achieved at U.S. company Centex Machining with the help of a FOBA M3000 marking station. "We have integrated a marking process that previously required twelve individual manufacturing steps and 18 hours of marking time into the marking station," explains the medical device manufacturer's production manager. The entire process now takes just three hours (two hours of setup time and one hour of marking time), which Centex Machining attributes not only to the rotary unit and the spacious marking field, but also to the integrated camera.

Equipping a marking unit with a 2-station rotary table and motorized Z-axis can also be a solution when the loading is done manually, to make the marking process faster and more user-friendly: with the help of a movable axis, for example, even a complex part can be marked at different positions without manual relocation. It can also already be helpful to switch from manually operated point-and-shoot marking to automated marking positioning with FOBA Mosaic, the software solution for automated mark alignment without part fixtures.

The selection of the appropriate marking system and possible automation depends on the type and quantity as well as the material of the workpieces, the required size of the marking field and the desired visual inspection before, during and after marking. Fiber laser marking systems such as FOBA Y.0201, the so-called "universal laser" are particularly suitable for versatile applications in many industries. Virtually all types of metal, plastics or other materials can be marked with FOBA's short pulse fiber lasers. Their high marking quality and easily integrated visual process control make direct part marking a safe comprehensive process.

www.fobalaser.com