www.ptreview.co.uk

05

'21

Written on Modified on

NSK training resolves bearing failures at steel plant

Unaware that rod mill chocks had been fitted with the incorrect spacers, maintenance technicians at the plant of a steel manufacturer were facing regular bearing failures and the need to source high-cost urgent replacements. However, the intervention of NSK – via best-practice training sessions – soon resolved the issue, delivering impressive annual savings of €46,190.

Maintenance technicians responsible for the rod rolling mill were oblivious to the correct way of calculating the size of spacers required for its bearing chocks. Instead, the team worked to a Standard Operating Procedure (SOP) that was 20 years old. Concerned about the costs of urgent replacements and downtime from five bearing failures a year, the steel plant turned to NSK and its AIP Added Value Programme.Following a comprehensive assessment of the failed bearings and chocks, expert NSK engineers identified the cause as the fitting of incorrectly sized spacers. This discovery instigated a number of value proposals, including training sessions delivered on-site by NSK’s team of specialists, who demonstrated the correct bearing assembly process. The new spacer calculations now feature in an updated and reissued version of the customer’s SOP.

At the same time, genuine NSK bearings have replaced the previous high-cost bearings, generating a further saving. Scheduled replacements can now take place at competitive pricing levels.

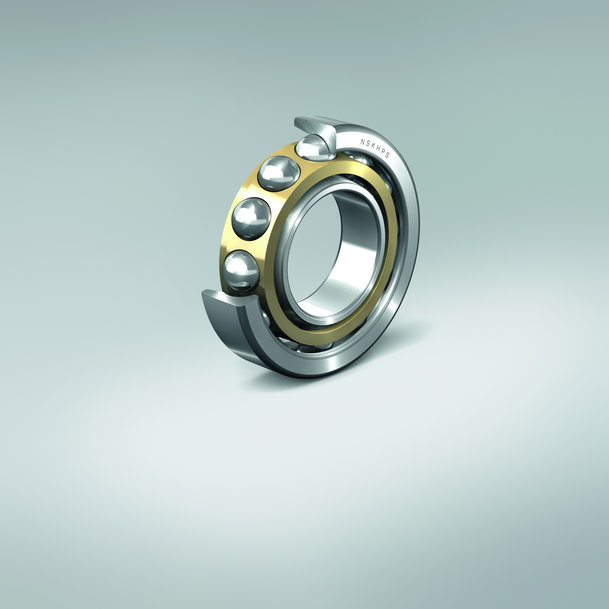

NSKHPS angular-contact ball bearings offer significant benefits to users of industrial machines such as those found in steel mills and the wider metal manufacturing sector. For instance, these bearings provide users with easy handling, long life, low vibration and quiet running. In addition, high-load, high-speed capability is matched by high dimensional and running accuracy.

A polyamide cage material is the first choice in standard applications, although the availability of other materials makes NSKHPS angular-contact ball bearings ideal for a variety of other industrial products, such as API pumps (using a machined brass cage) and screw compressors (L-PPS cage).

The adoption of NSKHPS bearings, in tandem with the updated SOP, has led to annual savings at the steel mill of €46,190, driven principally by fewer production losses, reduced maintenance time and lower bearing costs.

NSKHPS angular-contact ball bearings offer significant benefits to steel mills