www.ptreview.co.uk

26

'21

Written on Modified on

Making safety a priority: NexSafe brakes with functional safety certification

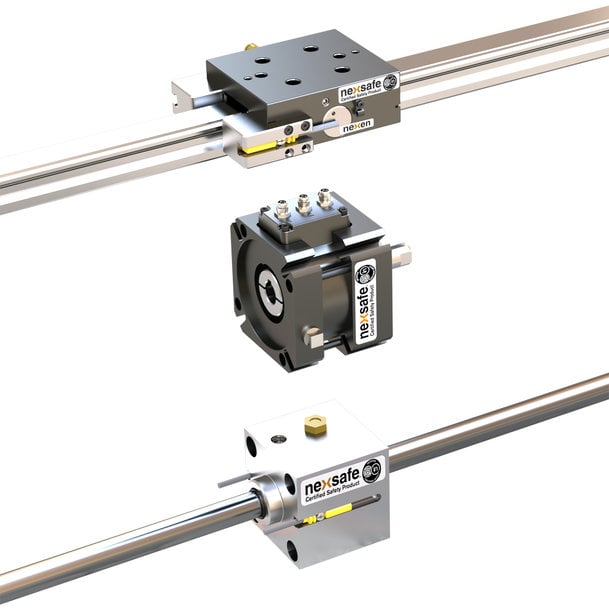

Nexen Group, Inc. now offers three of its brakes products with functional safety certification under its NexSafe trademark name. NexSafe functional safety certified rod locks, rail brakes and servomotor brakes can be used for machine operations such as holding, emergency stopping or positioning. They are ideal for applications where safety is a priority.

Functional safety

Functional safety reduces the risk of injury posed by the use of machinery in the face of operator error or mechanical failure. Building functional safety requires the design and fabrication of protective features responding to human errors, hardware failures, operational or environmental stress. ISO 13849-1 is a safety of machinery standard that assists in the design and integration of safety related parts of control systems or machines. This standard includes a system of categorizing the risk a machine poses, and the safety functions to mitigate that risk.

Certification program for industrial automation

Intertek, a company headquartered in London, provides assurance, inspection, product testing and certification. In July 2020 Intertek launched its Functional Safety Conformity Assessment Program for industrial automated machinery and robotics. The program offers manufacturers design evaluation, testing and certification with the Intertek Functional Safety (FS) Mark to signify compliance with rigorous standards for product safety and performance.

The first products in North America to earn the FS Mark are Nexen’s NexSafe rail brakes, servomotor brakes and rod locks.

Emergency stopping and holding applications

NexSafe functional safety certified brakes provide a verified, reliable solution that machine builders can depend on. With ISO 13849-1 Functional Safety Certification, NexSafe rod locks, rail brakes and servomotor brakes are ideal for operations such as holding, emergency stopping or positioning. They are an ideal fit for applications where safety is a priority. Optional operating mode sensors further ensure NexSafe products are a fit for safety channels designed for ISO 13849-1 categories B through 4 and performance levels PLa through PLe. In addition, NexSafe brakes are certified to meet IEC 61508, ISO 12100, ISO 13850, and ISO 4414 standards.

Rail brakes: compatible with most profile guide rails and carriages

Rail Brakes grip and hold profile guide rails in linear motion systems. The NexSafe rail brake is a compact, powerful brake compatible with most profile guide rails and carriages. Rail brakes can be equipped with sensors to detect engagement and disengagement. Guide rail brakes with mounted sensors are ideal for E-stop and redundant safety braking applications such as gantry axis braking, industrial door open/close locking, medical equipment and hospital beds, primary and secondary packaging, and window and door manufacturing.

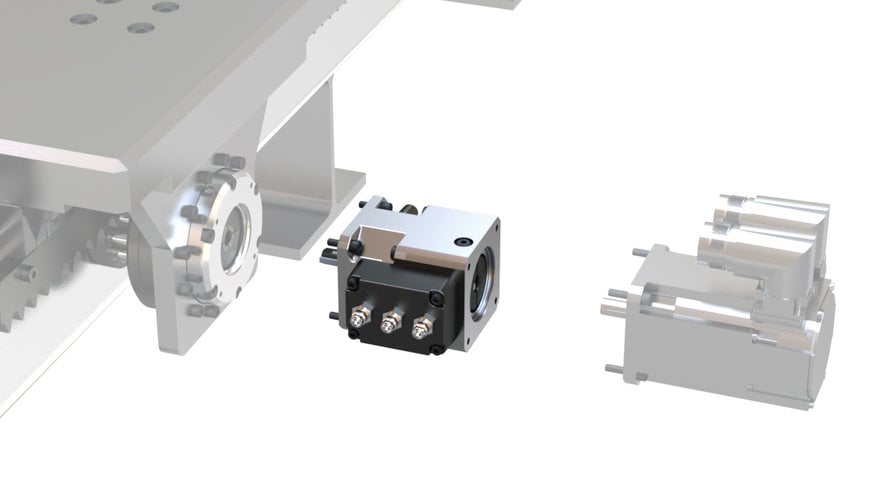

Servomotor brake: powerful high torque brake between servomotor and driven load

Servomotor brakes have been developed for braking on the shaft end of a servomotor or between a motor and gear reducer. The NexSafe servomotor brakes stop the load quickly and enhance safety with bidirectional braking capabilities. Typical applications include the production of automotive parts, cyclical operations, food production (IP67) and packaging, gantry routing, robotics, and semiconductors.

Rod locks: precision holding with guide rod systems and pneumatic cylinders

Rod locks can operate on round rails, linear rods, round shafts, and linear guide systems, or they can be mounted directly to an NFPA and ISO pneumatic cylinder. They are designed to grip and hold the piston rod of a pneumatic cylinder or a guide rod with extremely low backlash. They meet IP67 standards and can be equipped with sensors to detect engagement and disengagement. Rod locks are used for applications that require precise holding, fast engagement, and high cycle rates over millions of cycles such as automotive production, cyclical operations, food production (IP67), gantry routing, and platen presses.

The NexSafe servo brake shown here can include up to three sensors to monitor the disengagement condition, engagement condition, and wear. This feedback helps the brake satisfies the requirements for functional safety certification and deliver IIoT connectivity.

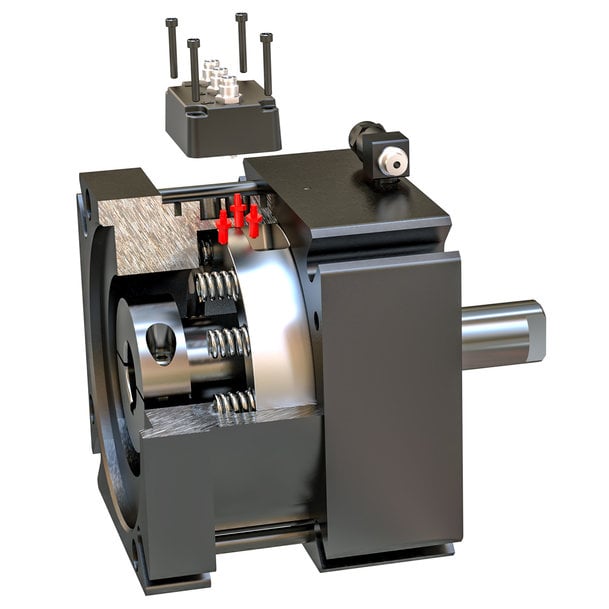

Functional safety features

Brake features to help achieve high levels of functional safety include multiple engagement springs that default to lock. The friction surfaces are equipped with a proprietary friction facing, tapered on both the inner and outer friction surfaces. Those surfaces apply the braking (locking) force via springs concurrently to both the rotating shaft and brake housing to hold the shaft from rotating, all with zero backlash. To ensure safe emergency stopping and holding, there are up to three operating-mode sensors for feedback.

These are essentially inductive proximity sensors to sense three different brake conditions: First, disengagement: the proximity sensor in the brake activates when rated air pressure enters the brake’s the piston circuit to essentially pull the friction-facing pair apart, for a disengaged (free-running motor torque) axis condition. Second, engagement: the proximity sensor in the brake activates when the piston and facing friction-surface pair move into engagement and application of braking (stopping) torque. Third, wear: this proximity sensor in the brake activates when the brake is engaged but the friction facing is worn enough to necessitate replacement.

The NexSafe servo brake has failsafe mechanical connections with the servomotor and gearbox; patented frustoconical friction-facing structures with tapers on both the outer and inner surfaces for simultaneous engagement with two mating surfaces; and optional sensors for feedback.

Time-tested technology, Industry 4.0 ready

With spring-engaged, air-released functionality, NexSafe devices default to the locked position, making them ideal for holding a load in position or for emergency stopping situations. They can be used in any orientation. Nexen has manufactured thousands of rail brakes, servomotor brakes and rod locks for a wide range of applications. NexSafe builds on that experience, retaining form, fit, and functionality, while seeking enhanced safety. Industry 4.0 is a standard option all on NexSafe devices.

www.nexengroup.com