www.ptreview.co.uk

28

'20

Written on Modified on

Renishaw encoders drive improvements in the performance of direct-drive motors

Haozhi Mechanical and Electrical (Haozhi), based in China, is an industry leader in direct-drive technology for machine tool and robotics applications.

Background

Direct-drive (DD) motors are electric motors that directly transmit power to the application without the use of mechanical reduction elements such as gears, pulleys, chains or belts.

DD technology for linear motors and rotary tables has matured in recent years. It has significantly improved the overall performance of machine tools, which has enabled corresponding improvements in the quality, speed and efficiency of production machining. These benefits help manufacturers to reduce machining times and to drive down costs.

Haozhi builds direct-drive rotary (DDR) tables and linear motors with integrated high-performance optical encoder systems from Renishaw, which give Haozhi products a substantial competitive advantage.

Qun Lei, Vice President of Haozhi, explains his company's role in the machine tool industry:

“Haozhi initially focused on producing machine tool motor spindles and, after many years of hard work, we are now the global market leaders. We have launched a wide range of spindle products aimed at different industries — including the world's fastest motor spindle that operates at up to 400 krpm with a rotational accuracy of 6 µm. We also manufacture machine tool rotary tables and linear motors, and are developing gear reducers and robotic joint products to cater for the rapidly growing robotics market. We export primarily to Southeast Asia and a number of European countries.”

We first came across Renishaw's advanced metrology products more than a decade ago and have enjoyed working with them ever since. When we decided to begin developing rotary tables, we chose their optical encoders without any hesitation as we have the utmost confidence in Renishaw's products.

Haozhi (China)

Challenges

General market trends for DDR motors include higher position accuracy, increased reliability, and lower maintenance costs.

In recent years, the use of direct-drive rotary (DDR) table technology has expanded into automated manufacturing and light-machining applications.

Rotary tables are usually deployed as either a fourth or fifth axis on CNC machining centres for precision light manufacturing, such as the machining of mobile phone and tablet cases. Alternatively, rotary tables are used in indexing table modules for automated production lines.

Many everyday consumer products require parts that have been precision machined on rotary tables with excellent accuracy and motion control performance in order to produce the smooth surfaces required.

The error budget of a motion control system, such as a rotary table, is affected by factors related to the machine structure, individual mechanical components, transmission mechanisms and position encoders.

Mechanical resonance is one of the most common problems designers face when trying to maximize either the command response or dynamic stiffness of traditional rotary tables driven by worm gears. One particular concern is the inertia mismatch between the load and the motor.

DDR tables eliminate many of the mechanical resonances associated with traditional rotary tables and enable the design of high-performance systems which are optimised for the speed and torque requirements of the application.

For Haozhi, encoders are one of the most critical components in their motion control products. Important encoder errors for rotary motors include sub-divisional error (SDE), jitter, installation error (which includes scale eccentricity), scale graduation error and the compliance of the coupling between the motor and the encoder rotary scale.

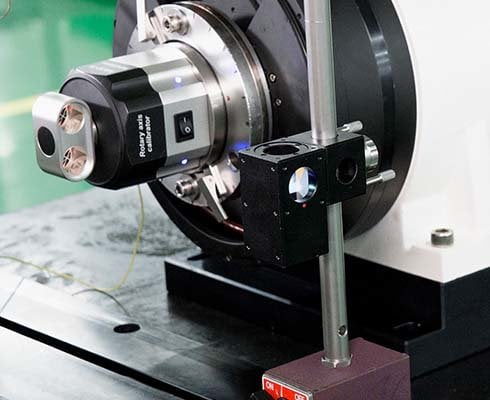

Haozhi employs Renishaw's XL-80 interferometer and XR20-W rotary axis calibrator for inspection of its linear motors and rotary tables

Solution

Renishaw has a significant presence in the machine tool sector and has cultivated a successful relationship with Haozhi over many years.

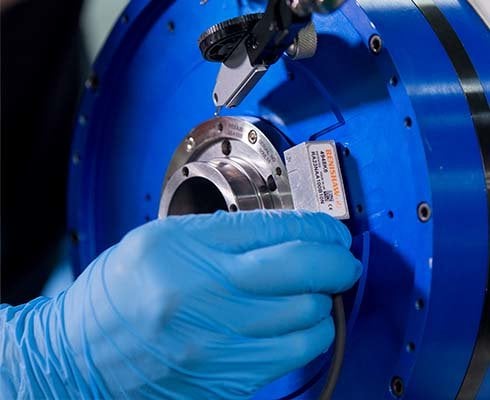

Haozhi has selected the RESOLUTE absolute optical encoder series with RESA rings for its new family of rotary tables.

“We first came across Renishaw's advanced metrology products more than a decade ago and have enjoyed working with them ever since. When we decided to begin developing rotary tables, we chose their optical encoders without any hesitation as we have the utmost confidence in Renishaw's products. Our experience has shown that their optical encoders are easy to install and that our engineers are able to assemble them quickly.

Renishaw's expert team also provides outstanding aftersales service, and they helped with any issues that we encountered during the early development stages of this project.” Mr Lei explains.

The RESOLUTE RESA system delivers class-leading performance and features an absolute ring with a fine 30 µm-pitch scale, SDE of just ±40 nm and jitter of less than 10 nm RMS.

Two types of RESA ring are available, each with a different method of installation. One variant features Renishaw's patented taper mount design, which reduces demand for tightly-tolerance machined components and eliminates eccentricity; and the other features a low-profile ring design that offers reduced rotational inertia.

Haozhi's direct-drive rotary tables are fitted with RESOLUTE series absolute encoders to enhance motion control accuracy

Renishaw's non-contact optical encoders eliminate backlash, shaft wind-up (torsion) and other mechanical hysteresis errors that are inherent in traditional enclosed encoders.

RESOLUTE encoders also feature a wide range of industry standard serial comms protocols to enable direct communications with the customer's controller and provide real-time position data.

Mr Lei continues: “In terms of compatibility and the diversity of the product range — there are definite advantages to Renishaw encoders. Many controller manufacturers out there offer a huge variety of available communications protocols: RESOLUTE absolute optical encoders support most mainstream industrial comms protocols including FANUC, Mitsubishi, Siemens DRIVE-CLiQ and BiSS®. Furthermore, the encoder readhead and ring dimensions are always the same irrespective of the serial protocol output option which eliminates the need to modify our structural designs.”

Haozhi has also developed linear motors, using Renishaw's traditional RG2 and RG4 encoder ranges, that are fully capable of meeting the needs of demanding industries including computers, communications and consumer electronics (3C).

Mr Lei highlights the role of Renishaw laser calibration products in the quality control testing of Haozhi's linear and rotary stages:

“In order to make a good job of quality control, we use Renishaw XL-80 laser interferometers with XR20-W rotary axis calibrators to test all our linear motors and rotary tables. The accuracy, ease of use and reliability of the testing equipment were decisive factors.”

Results

By integrating Renishaw's RESOLUTE absolute optical encoder system into its CNC rotary tables, Haozhi has further assured the accuracy, reliability and superior motion control performance of its products.

Haozhi rotary tables offer positioning accuracy of ±10 arc seconds, repeatable precision of ±2 arc seconds and a wide range of torques and speeds. While Haozhi linear motors offer a bidirectional positioning accuracy of ±2 µm, a continuous thrust range of 0.2–4.0 kN, and a peak thrust range of 1–12 kN.

RESOLUTE encoders also feature a high level of ingress protection which has enabled Haozhi to build rotary tables with an IP68 rating in some cases.

Renishaw's long-term partnership with Haozhi has promoted a more integrated product development strategy that helps the company to maintain its position at the cutting edge of DD motor technology.

www.renishaw.com