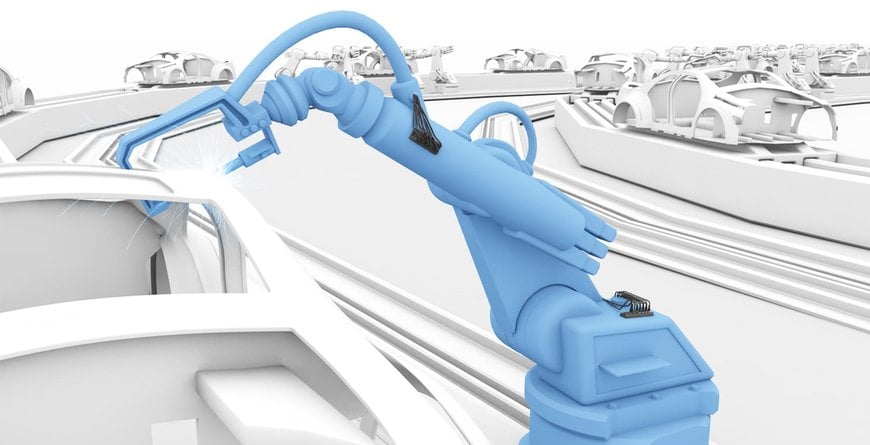

TPE-Jacketed Cables with Silicone Tubing Withstand Harsh Welding Conditions

New Balluff Cables Deliver Higher Temperature Resistance, Safeguard Against Weld Spatter.

Balluff’s newest family of TPE jacketed cables and splitters with silicone tubing withstand the harsh conditions of welding environments. They operate in increased ambient temperatures and resist thermal shocks, weld sparks and spatter.

Thermoplastic Elastomer (TPE) jackets offer weld spark resistance and a high flex life rating of more than 10 million cycles. A silicone tube over the cable which is overmolded to the connector creates an insulating air pocket that increases the temperature resistance to up to 250 ºC. The silicone tube also prevents occasional weld spatter and sparks from burning through the cable. The cable’s locking nut is coated with PTFE, preventing spatter buildup that can destroy a sensor when disconnecting it.

With cables available in lengths from 0.3 m to 2.0 m and with multiple connector types, they provide the needed protection for welding applications.

Splitters in this product family come in lengths from 0.3 meters to 1.0 meters. The splitters specifically provide high-level protection of cables to I/O blocks mounted in a weld area. To access both I/O on a port you need a splitter to break out the two separate legs. Balluff’s new splitter cables offer the same TPE jackets with added silicone tubes overmolded to the connectors.

This means that you can now fully utilize I/O blocks and protect cables where they are vulnerable, reducing downtime in welding cells due to cable failure.

Key features:

- Operating temperature (fixed) -60…250 ºC

- Air inside silicone tube insulates the cable

- Silicone tube overmolded into the head to prevent ingress

- Resistant to thermal shocks

- PTFE coated nut prevents debris from sticking

- Cables lengths 0.3 m…2.0 m; splitter lengths 0.3 m…1.0 m