FEV LAUNCHES NEW SOLUTIONS FOR HIGH VOLTAGE BATTERY TESTING

In May 2020 FEV, a globally leading independent international service provider of vehicle and powertrain development for hardware and software, had announced to complete the initial operation of the world’s largest battery development center eDLP by the third quarter of 2020.

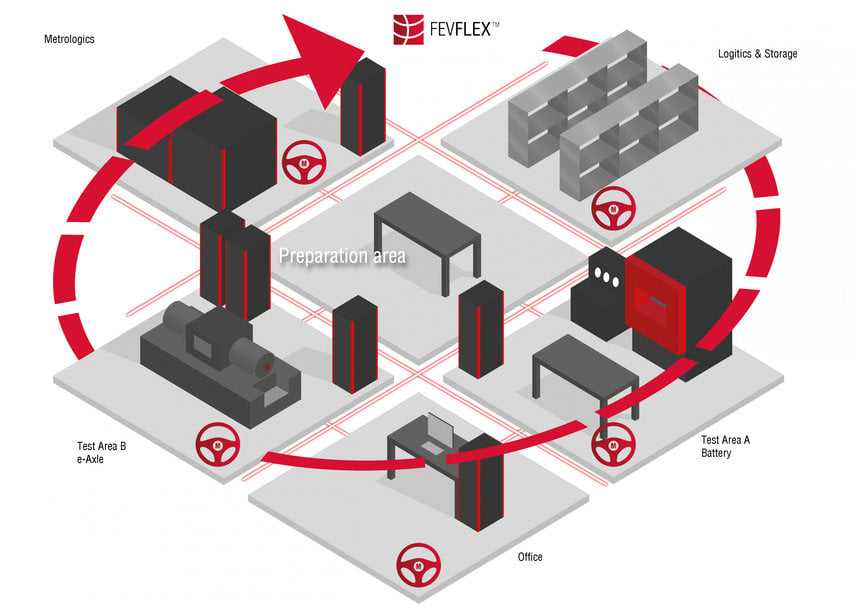

FEVFLEX, FEV’s information system, manages the flow, processes and data of a testing project. MORPHEE®, the FEV automation system, monitors equipment and test beds of the testing center

In addition, FEV STS – the software and testing solutions division at FEV – is launching a new range of innovative applications for battery testing in the field of hybrid and electric vehicles. The FEV automation system MORPHEE® and the information system FEVFLEX are available right now and are already operating in various European and Asian battery development centers. This includes the eDLP as the synthesis of STS’ E-mobility competencies.

Due to the increasing need for high-voltage battery development for electric vehicles, corresponding testing facilities are gaining in importance significantly. Addressing this need, FEV’s software and testing solutions division STS is introducing a new range of high-tech applications for battery testing. Based on FEV’s 15 years of experience in the field of automotive battery testing, the company’s latest automation software MORPHEE® and its FEVFLEX information management software feature standardized hardware solutions as well as engineering software customizable to all testing requirements. "Optimal work- and information flow is key in battery testing centers,” said Martin Rebbert, group vice president of FEV STS. “Just imagine the huge number of data being processed in a battery development center like FEV’s eDLP which is the largest of its kind globally. A 95 percent operation rate is standard for our test benches, generally. Nevertheless, it is our aim to further improve these figures.”

Just one single information system is managing the entire testing processes from start to finish, which includes the following steps:

- Tagging received and to be tested battery packs, modules or cells with a dedicated bar code

- Assignment of a secure storage

- Equipping the so called UUT (Unit Under Test) with measurement devices in the prep zone

- Mounting on the according test bench

A further important ease of processing is achieved by using just one format for the equipment data and measurement data in the result file. These solutions form the basis for the operating processes in all FEV battery test centers like eDLP in the Leipzig area (Germany) and the company’s facility close to Paris (France).

Battery test cells designed by FEV STS: cell testing case

The 12,000 m² eDLP complex not only features facilities for the electrical testing of battery modules and complete high-voltage batteries but also for abuse testing covering short-circuit tests, simulation of internal cell errors as well as acceleration and impact tests simulating a severe accident. The test chamber volume measures approximately 600 m³. This volume is distributed over 54 climate chambers with an electrical output of 30,000 kW making the eDLP battery testing center the largest independent facility of its kind in the world.

For the French location FEV decided to pay particular attention to cell tests as the raw material for batteries with a testing capacity of 300 cells on site. Characterization and aging tests performed on selected cells can be extrapolated to the complete battery.

Additionally the company operates battery testing facilities in Aachen and Munich (both Germany) as well as in Coventry (UK) and Beijing (China).

FEV STS’ testing solutions have performed multiple validation loops successfully. They have been developed and designed with the aim to shorten development efforts and time for the company’s industry partners, the OEMs and suppliers.

www.fev.com