www.ptreview.co.uk

27

'20

Written on Modified on

Nicolás Correa moves into top gear with REDEX technology

Two recently introduced milling machines from Nicolás Correa are leveraging the benefits of the latest-generation of the Rack & Pinion drives technology from REDEX. Chosing the advanced REDEX drive train is the way to enable superior dynamic performance for users of the new FOX-M Gantry-type CNC milling machine, and the FENIX travelling column CNC milling machine.

The FOX M represents a new and innovative concept of Gantry-type machine which combines traditional roughing capacity with the speed and precision of high-performance machining. It features a unique system which controls the temperature generated in the vertical axis of the machine. While high dynamic capacity of 25-30 m/min in the X and Y are supported by V-shaped linear guideways, the Z axis features a box type guideway cooled with water, allowing up to 30 m/min of speed and ensuring an optimum damping capacity even when the ram is fully extended.

A FOX M was present on Nicolás Correa's stand at the last AMB exhibition in Stuttgart, where it was arguably the biggest machine at the show. Seven models are available, spanning X-axis traverse distances of 5.000 to 14.000 mm. The 6.000 rpm spindle is available with two different spindle motors: 37 kW /1298 Nm or 52 kW / 1375 Nm. Both options are offered with either ISO-50 Big Plus or HSK-100 taper. Moreover, UDX milling head is also available in this model, featuring 10,000 rpm with 30 kW / 620 Nm, mechanically transmitted through bevel gears; unique in the world.

One of the main differentiators with Correa FOX M milling machines is the head technology. For instance, the company’s UAD universal and OAD orthogonal indexing milling heads are unique in the market, with patented technology allowing rotation every 0.02°. And the Correa two-axis ’twist-type’ contouring head can be alternately supplied to those seeking five-axis machining solutions. This type of head features high performance electro-spindle or spindle geared transmission.

Typical applications for the FOX M include construction machinery components, railway parts, machine tool components and wind energy frames, etc.

The FENIX is another recent addition to Nicolás Correa portfolio, introducing a new concept of travelling column machine with lateral RAM. Highly robust, the FENIX is based on a system of L-guided RAM technology, with high precision enabled through a mechanical system of RAM droop correction.

A flexible machine ideal for both roughing and finishing operations, FENIX is available in X-axis travels of 4.000 to 25.000 mm. The 6.000 rpm UAD milling head features 33 kW / 990 Nm. Both UAD and two-axis contouring heads are available for applications that include artillery guns, wind energy hubs, heat exchangers and large rotors, to list just a few.

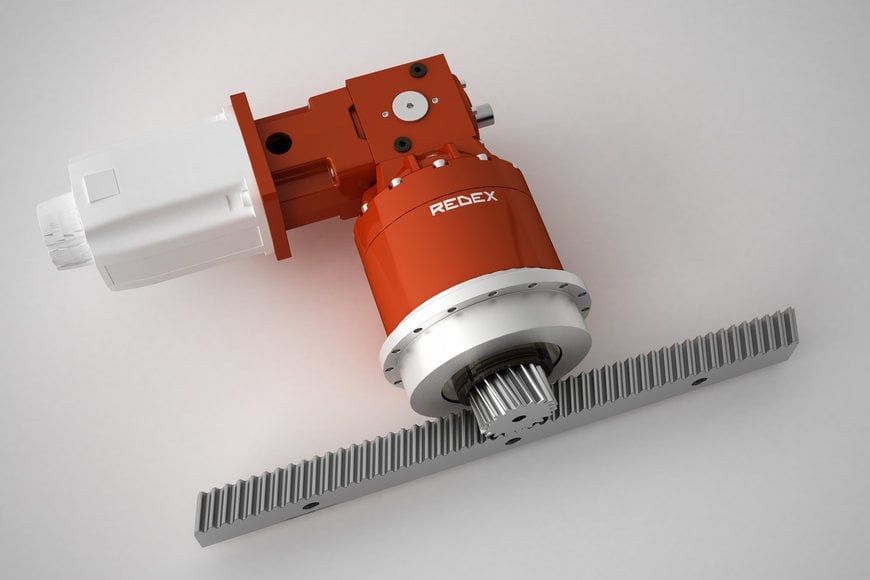

A common denominator between the FOX M and FENIX machines is that they both leverage the benefits of the latest REDEX planetary drive-train technology in the rack & pinion X axis drive, especially featuring the latest developments that reduce vibration and noise, while improving precision and service life.

This exciting development is an example of how REDEX continues to focus its efforts in the most challenging areas, for instance by still focusing efforts to evolved the planetary gear train to always reduce vibration, noise and transmission errors.

Among many others, that's one of the reasons why Javier Hernando, Technical Director at Nicolás Correa, has confirmed that using REDEX high-tech rack & pinion drives for linear axis has clearly improved the vibration and accuracy performance of the X axis of the FOX M and FENIX . A solution which provides users of these machines with superior output torsional stiffness, ultra-high output radial stiffness and tilting moment, higher input speeds, optimal preload, and superior acceleration and torque density.

Moving forward, REDEX gearbox solutions will be at heart of many future machine-tool developments from Nicolás Correa.

Nicolàs Correa latest expriences once again clearly shown that REDEX constant aim is to meet all the needs of machine-tool builders seeking the latest advances in rack and pinion drives, planetary servo-reducers, spindle drive gearboxes.

The company skills also includes differential drives, right-angle bevel gearboxes, multi-speed gearboxes and a host of associated products.

All over the world, REDEX works with its customers on a close partnership basis, not only in terms of product quality and reliability, but with an enhanced added value through its strongly reknown before- and after-sales service standing on its local service centers.