www.ptreview.co.uk

30

'19

Written on Modified on

New version of M2Web offers easy monitoring of KPI’s from Ewon-connected machines

HMS Networks now announces a new version of the M2Web service which enables users of Ewon® Flexy products to instantly monitor KPI’s, Key Performance Indicators, from remotely located machines. Using a standard PC, tablet or smartphone, Machine Builders and End Users get full insight into their installations thanks to a new intuitive graphical interface, a mobile-friendly responsive view, and a map view of all connected machines.

The ability to quickly check the status of machines is becoming more and more important for machine builders and end users. However, full IIoT solutions are often too complex, and too time consuming and costly to deploy. HMS targets this situation with M2Web, an innovate service which is included free of charge for all Ewon Flexy products registered on the Talk2M® secure cloud platform.

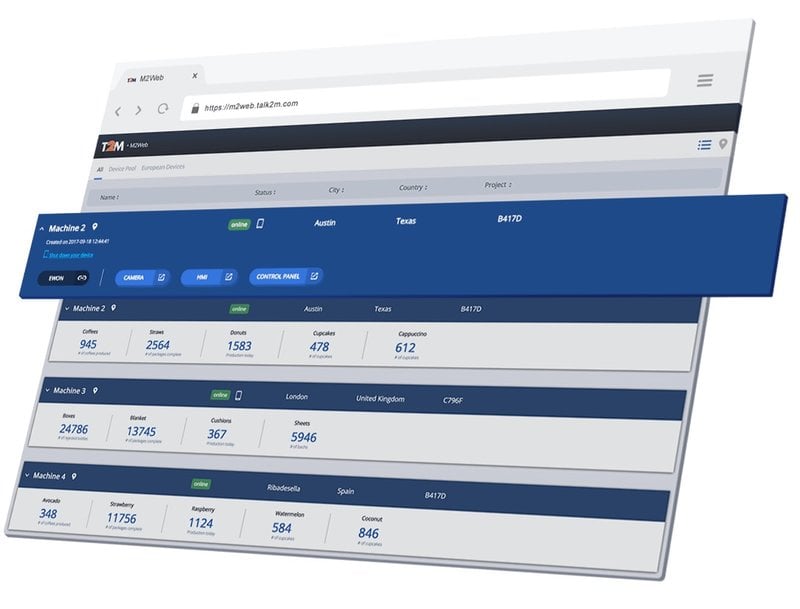

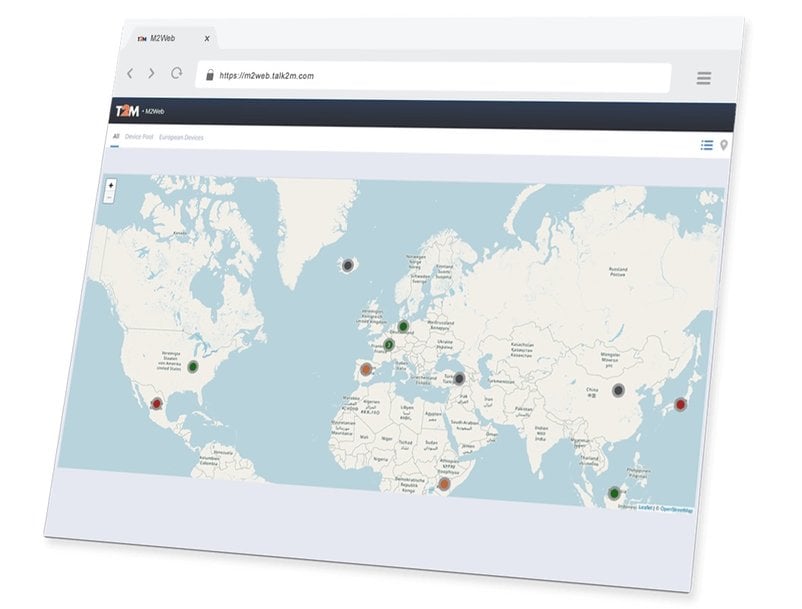

With M2Web, users benefit from secure browser-based mobile access to KPI’s from remote machines via Ewon Flexy products, enabling users to connect to e.g. a remote HMI, web server, PC, panels and more. M2Web does not require any software installation – the user simply needs to open a standard browser. In M2Web, the information is presented in a modern responsive graphical interface, and a map view has been implemented to enable a global perspective of installed machines in the field.

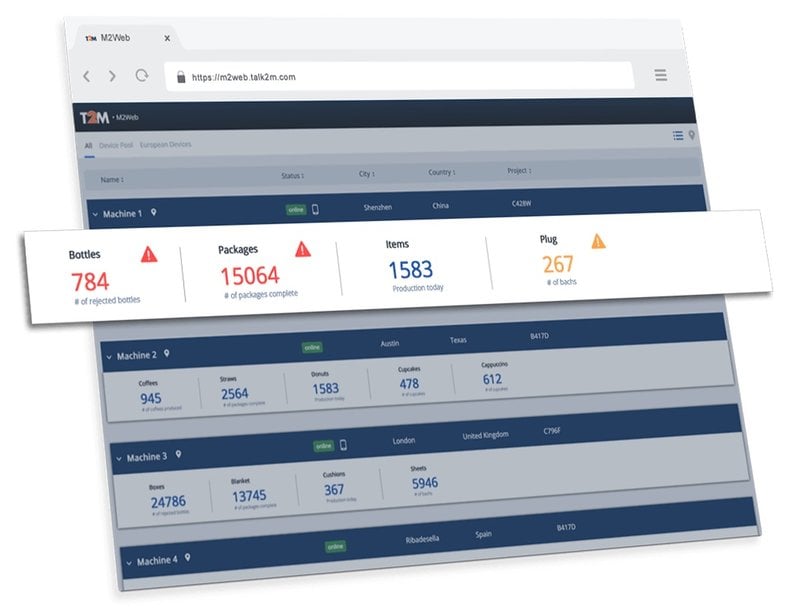

The brand-new KPI feature enables users to easily get instant information about the health and performance of all connected machines. The user simply defines up to 6 desired KPIs by selecting parameters inside the tag-database of each Ewon Flexy. Each KPI visually displays the alarm status: Blue for normal state, Yellow for warning, and Red for Alarm.

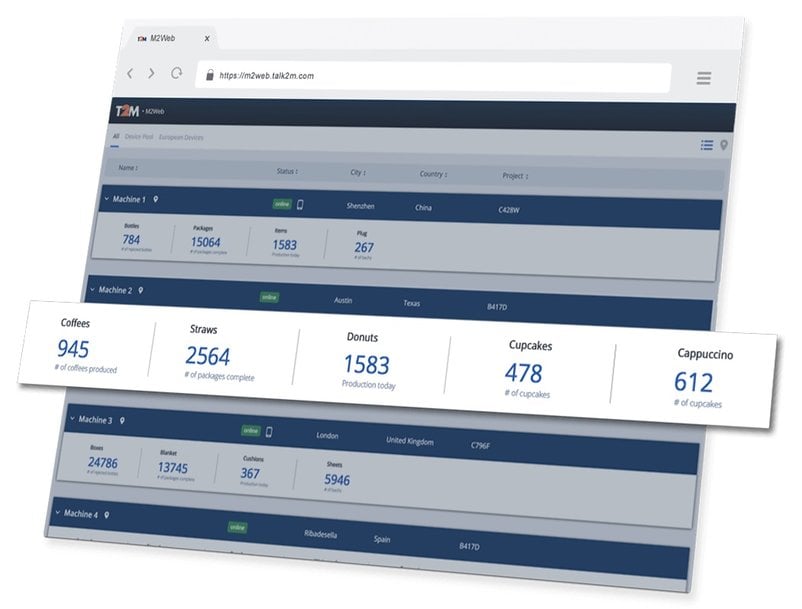

While M2Web is an easy way for machine builders to monitor all their machine KPIs in one place, it is also a very handy tool for end users. A machine builder can easily put M2Web at the disposal of the end user customers, allowing each end user to utilize M2Web as an easy monitoring tool, including a summarized view of all connected machines on site.

Powered by the proven Talk2M secure cloud platform from HMS Networks, M2Web provides machines builders, end users – and their system integrators - a new way to instantly access their installations from any device, such as a PC, tablet or smartphone, all. Thanks to the key information made available through M2Web, users can avoid any production downtime and improve operational efficiency.

With M2Web, users benefit from secure browser-based mobile access to KPI’s from remote machines via Ewon Flexy products, enabling users to connect to e.g. a remote HMI, web server, PC, panels and more. M2Web does not require any software installation – the user simply needs to open a standard browser. In M2Web, the information is presented in a modern responsive graphical interface, and a map view has been implemented to enable a global perspective of installed machines in the field.

The brand-new KPI feature enables users to easily get instant information about the health and performance of all connected machines. The user simply defines up to 6 desired KPIs by selecting parameters inside the tag-database of each Ewon Flexy. Each KPI visually displays the alarm status: Blue for normal state, Yellow for warning, and Red for Alarm.

While M2Web is an easy way for machine builders to monitor all their machine KPIs in one place, it is also a very handy tool for end users. A machine builder can easily put M2Web at the disposal of the end user customers, allowing each end user to utilize M2Web as an easy monitoring tool, including a summarized view of all connected machines on site.

Powered by the proven Talk2M secure cloud platform from HMS Networks, M2Web provides machines builders, end users – and their system integrators - a new way to instantly access their installations from any device, such as a PC, tablet or smartphone, all. Thanks to the key information made available through M2Web, users can avoid any production downtime and improve operational efficiency.

For more information, visit www.ewon.biz/support.