Sleight of hand

Guided Operator Solutions help eliminate typical assembly problems.

With Mitsubishi Electric’s guided operator solutions, picking mistakes can be easily eliminated, helping to reduce waste, improve quality and boost productivity.

By eliminating typical problems such as picking the wrong parts with a similar shape or name, picking and assembling parts out of sequence or just missing a part from a sequence, Mitsubishi Electric’s integrated guided operator solutions make workers’ hands faster and more reliable, resulting in appreciable improvements in efficiency for manufacturers.

Based on the Japanese principles of the ‘Poka Yoke’ method of eliminating mistakes before they can occur, guided operator solutions are a simple, versatile system which do away with the need for parts lists or operator instructions,delivering faster assembly times, increased assembly quality and reduced requirements for operator training.

Beautifully simple

Traditionally, workers are required to pick a number of different parts or products from bins in sequence. The chances of them doing this with 100% reliability, 100% of the time, is small.

At the very least, a significant proportion of time will be taken up searching for the right part and validating the part number. In a worst case and all too common scenario, a mistake goes unnoticed until it is further up the production line, if indeed it is noticed at all.

Mitsubishi Electric guided operator solutions ensures that none of this can happen by guiding the worker to the correct bin, possibly by lighting an indicator or by opening a shutter and requiring acknowledgement of a successful pick. Thus, their picking becomes more reliable and mistake-free and also much faster, improving quality and productivity in the process.

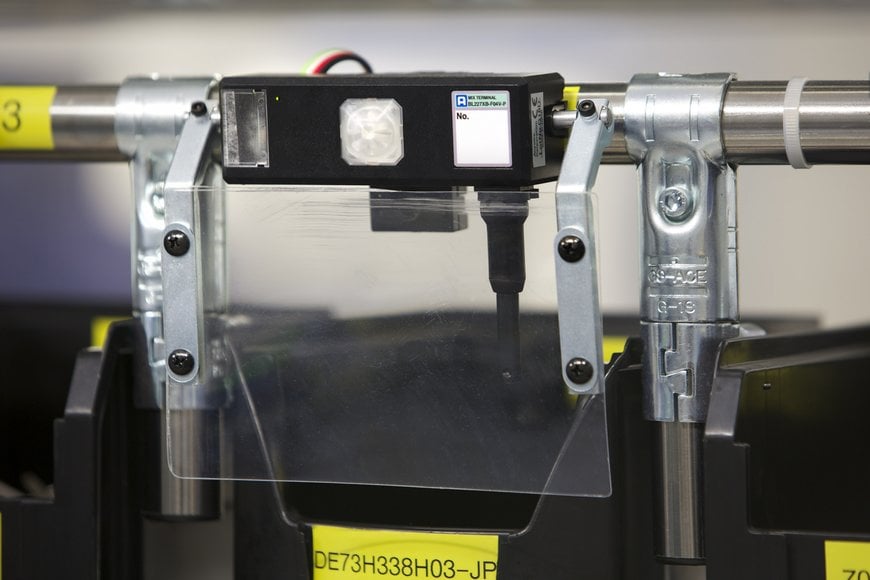

Terminals are easily installed on pipe racking and connected via a dedicated cable that avoids the need for multiple cables to the main controller. Intuitive connectors enable fast installation of networks, while terminals can be quickly set up with an address writer using dedicated software. These can be successfully mapped to a controller.

Highly versatile

The variety of terminals ensure that the solution is suitable for just about any application. Photoelectric sensors provide options for applications where high speed picking is essential, or for more cost-sensitive applications, an array of push button and lever feedback actuators are available.

The power of integration

Where assembly tasks must fit into a wider operational environment, dedicated bridges connect stations over CC-Link and CC-Link IE networks to allow connectivity to multiple picking applications within a plant. High speed data communication enables synchronization of tasks and also allows assembly cells to be distributed according to the needs of the production site.

Fully expandable

Central to the guided operator solutions are Mitsubishi Electric’s controllers with dedicated masters communicating with a network of terminals. By connecting other devices to the controller, such as bar code scanners, electric screwdriver or vision systems, guided operator solutions can be tuned to the exact needs of the operator. Mitsubishi Electric’s intuitive GOT HMIs can help achieve further enhancements and drive as well as robotic technology can be integrated into the manufacturing cell.

Guided operator solutions offer a variety of terminal types, they range from a simple LED and push button device through to door operated terminals. Options for lever switch and photoelectric terminals are also available.