www.ptreview.co.uk

23

'18

Written on Modified on

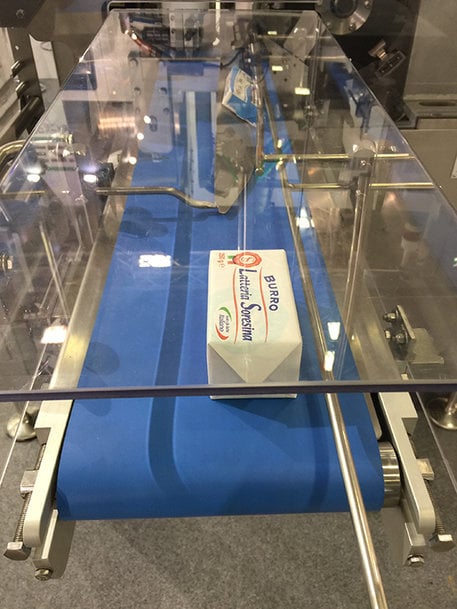

Ing. E. Vezzadini uses Interroll in its butter packaging machinery

The Italian company is the market leader for butter packaging machinery and has selected Interroll Drum Motors to help convey its delicate product on its machines.

Ing. E. Vezzadini expressed his satisfaction with what he considers a significant technological improvement in the prestigious company's machines: "We have been designing and building automatic packaging machines for dairy products and cooking fats for over 60 years”. “Our market is the entire world; to maintain our leading position in our field, we need to focus on continuous improvement. To this effect, Interroll has enabled us to take a huge step forward, not only in terms of technology but also in terms of sustainability and quality."

Interroll Drum Motors are perfect for use in the food industry as their IP66/IP69k rating satisfies EHEDG hygienic equipment design criteria, follows the Ecolab cleaning procedure, and complies with US Food and Drug Administration (FDA) and European Union EC 1935-2004 regulations.

Ing E.Vezzadini & C. S.r.l.'s packaging machines are mainly used in creameries around the world, as well as by food processing companies producing cheese spread and margarine.

Packaging machines for this type of product combine precision mechanics and electronics, and the extent to which the machines can be customized is extremely high. Vezzadini products are distinguished by their premium quality and artisan manufacturing. The company's automated machines must produce packs of butter at a rate of 100 blocks a minute.

All of this has to happen with the utmost precision and the greatest possible fluidity.

The decision to use an Interroll Drum Motor was influenced by the company's need to make its packaging machines less bulky, more efficient and 100 percent safe with regard to hygiene. The high-efficiency Interroll Drum Motor is easy to fit, covers a vast range of services and is virtually maintenance-free.

Ing. E. Vezzadini chose Interroll Drum Motors after seeing the clear benefits of using less bulky drum motors in place of conventional gear motors. The fact that the motor, gearbox and bearings are housed inside the drum means that drum motors require a lot less space than other types of motors. The belt conveyor can be made more compact and installed in smaller spaces. Moreover, drum motors are considerably faster and easier to fit: On average, in fact, they can be installed in 25 percent less time than is required to install a conventional drive system with multiple components, according to a recent study by the University of Parma. Reducing the number of components results in lower costs to manufacture the belt conveyor and purchase the components themselves.

Low-wear Interroll Drum Motors provide full performance even in harsh environments where water, fine dust, grit, chemical substances, fats and oils are present. They can even be subjected to high-pressure cleaning.

Moreover, thanks to their smooth, stainless steel surface and fully encapsulated hermetic structure, Interroll Drum Motors are exceptionally hygienic.

Interroll Drum Motors offer up to 78 percent efficiency in asynchronous design and as much as 83 percent efficiency in synchronous design, clearly demonstrating just how energy efficient they are. They have no protruding parts and, with their fixed external shafts, they are probably the safest motors on the market for ultramodern handling systems. Being internal, the components of the motors are protected from outside influences, which means they require almost no maintenance.

Claudio Carnino, Interroll Italy Commercial Director and Country Manager Italy, sees this as confirmation.

"Ing E. Vezzadini’s decision is yet a further confirmation of the superiority of Interroll's Drum Motor,” he said. “This also has been verified by a recent comparative study conducted by the University of Parma. The Interroll Drum Motors are enabling Ing. E. Vezzadini to progress in terms of efficiency, reducing the bulkiness of its machinery and ensuring hygiene. The Interroll Drum Motors are the only motors certified by the EHEDG."

Since 2017, Ing E. Vezzadini has been a partner in the global Rolling On Interroll program, which is designed to provide long-term support for machine manufacturers and system integrators, as well as to encourage involved partners to share their experiences in creating efficient materials handling solutions.

Contact

Martin Regnet

Global PR Manager

Interroll (Schweiz) AG

Via Gorelle 3 │ 6592 Sant'Antonino │ Switzerland

+41 91 850 25 21

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.interroll.com