www.ptreview.co.uk

17

'26

Written on Modified on

AI-driven picking with 3D vision for intralogistics

Basler introduces the ItemPickAI software module for AI-based object recognition and grasp point detection, designed for precise robot-assisted picking of consumer goods in complex warehouse environments.

www.baslerweb.com

As automation continues to expand in warehouse logistics, requirements for flexible and precise picking systems are increasing. The ItemPickAI software module has been developed to optimize robotic pick-and-place processes by combining AI-based object recognition with 3D vision technology. The solution enables reliable identification of consumer goods — including food products, personal care items, and electronics — even in densely packed containers, and calculates precise grasp points for robotic systems.

Precise picking in complex scenarios

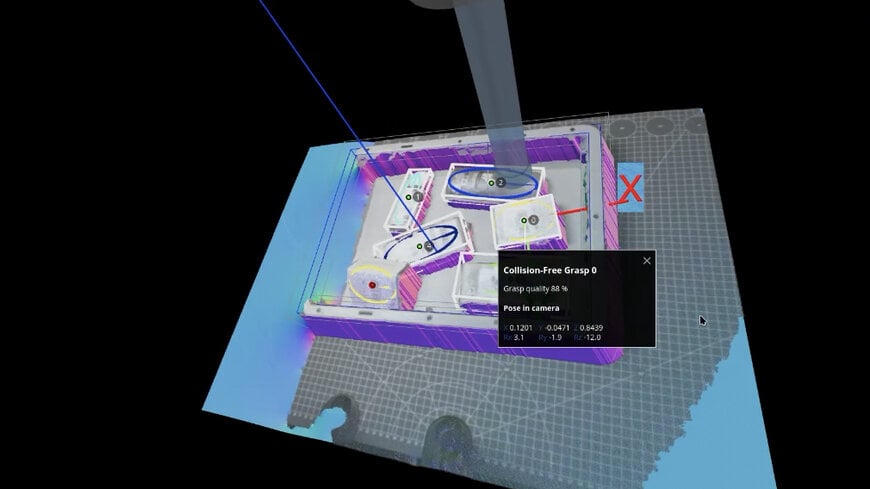

Automated picking systems often face challenges when handling products with varying shapes and arrangements. ItemPickAI addresses these requirements through AI-based analysis of 2D and 3D image data. The software detects objects in cluttered or mixed bins and determines optimal grasp positions, helping reduce error rates and minimize product damage.

Using a dedicated model type for consumer goods, the system calculates grasp points independently of the gripper type, such as suction grippers or two-finger grippers. Grasp poses are transmitted as complete transformations to the robot system — for example as homogeneous transformation matrices or as translation plus quaternion — enabling direct integration into existing robot control systems.

AI-based collision avoidance

A key feature of the solution is intelligent collision detection. Potential grasp points are evaluated for possible collisions with load carriers, adjacent objects, or the surrounding environment. Based on 3D point cloud analysis, the software assesses distances between the gripper geometry and nearby structures and provides status feedback to the robot controller to ensure safe picking operations.

This approach supports damage-free handling even for challenging surfaces such as glossy or partially transparent packaging.

Efficiency gains through AI and real-time processing

AI analysis is performed in real time to support high-speed picking workflows. Neural networks dynamically calculate grasp points, while additional information about available grasp surface areas helps automatically filter unsuitable positions. This improves process reliability and enables selection of stable grasping positions.

The solution is scalable and suitable for different warehouse sizes and a wide range of consumer goods categories, enabling higher flexibility while improving efficiency and reducing errors.

Integration with robot systems and 3D vision platforms

ItemPickAI integrates via standardized interfaces such as GenICam or GigE Vision and supports multiple robot brands. Integration packages are available for KUKA and Universal Robots, along with generic interfaces for ABB, FANUC, and Techman, with additional platforms planned.

For scene acquisition, the system uses data from 3D cameras such as Stereo visard or Stereo ace, which provide accurate depth perception. The 3D Camera Cube acts as an embedded processing platform for compute-intensive applications, while Randomdot projectors enhance depth detection by projecting high-resolution patterns onto the scene.

By combining AI-based vision, flexible robot integration, and precise grasp point analysis, ItemPickAI provides a scalable solution for efficient and automated picking processes in modern logistics environments.

www.baslerweb.com