www.ptreview.co.uk

22

'26

Written on Modified on

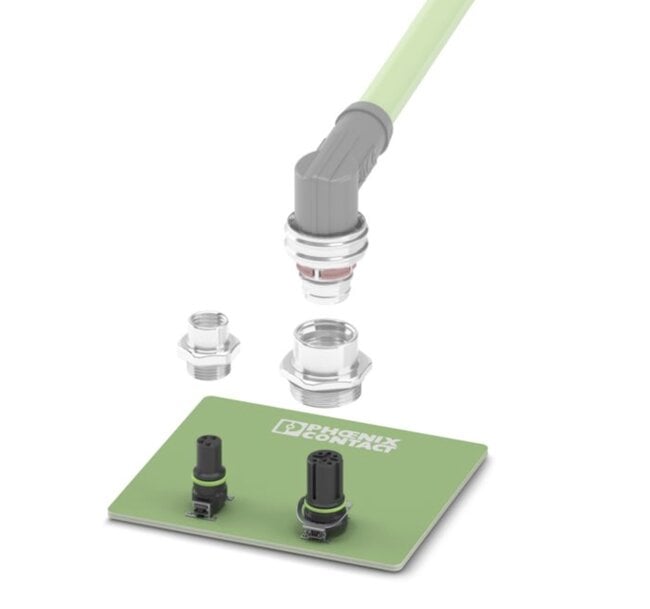

SMT-Compatible M8 and M12 Device Connectors

Phoenix Contact expands its device connector portfolio to support automated SMT assembly for data, signal, and power transmission in industrial electronics.

www.phoenixcontact.com

Phoenix Contact has extended its range of M8 and M12 device connectors with new surface-mount variants designed for direct integration into SMT soldering processes, targeting compact and automated device manufacturing.

Expansion of SMT-capable connector technology

The newly introduced M8 and M12 connectors are designed specifically for surface-mount technology, enabling direct placement on printed circuit boards and compatibility with standard reflow soldering processes. This approach supports automated assembly lines and reduces manual handling steps during device production, which is increasingly relevant in high-volume industrial electronics manufacturing.

The connectors are intended for the transmission of data, signals, and power, addressing typical requirements in automation technology, machinery, and sensor-based systems where compact interfaces and reliable connectivity are required.

Variants and application flexibility

The M12 SMD connectors are available with multiple pin assignments and codings. This allows their use across different communication and power interfaces within a single mechanical form factor. Such flexibility supports standardized device designs while accommodating varying electrical requirements, including mixed-signal and power applications.

Uniform installation geometry across the connector variants simplifies PCB layout and device enclosure design. A consistent installation height enables designers to use different codings or pin configurations without modifying the overall mechanical design of the device.

Design features supporting automated assembly

The connectors have been developed with automated manufacturing in mind. A revised shielding concept reduces mounting and spring forces, which facilitates placement during SMT assembly and contributes to reliable shielding continuity once soldered. Effective shielding transmission is essential for maintaining signal integrity in electrically noisy industrial environments, particularly in applications involving high-speed data or mixed power and signal transmission.

Shortened alignment pins allow the printed circuit board to be assembled on both sides, increasing layout flexibility and supporting higher component density. This is particularly relevant for compact devices where board space is limited and double-sided assembly is required.

Mechanical interface and future compliance

In combination with push-pull housing screw connections, the connectors support tool-free mating and demating while maintaining mechanical stability. This interface concept is intended to support future device generations that require faster installation and maintenance without compromising connection reliability.

The connectors comply with the requirements of RoHS II without relying on exemption 6c. This ensures conformity with current and anticipated regulatory requirements for hazardous substances, supporting long-term product availability and use in regulated markets.

Target applications

The SMT-compatible M8 and M12 connectors are suited for industrial automation devices, sensor and actuator interfaces, and compact control units where automated production, consistent installation geometry, and regulatory compliance are key design criteria. By combining SMT processing capability with standardized circular connector interfaces, the portfolio extension addresses evolving requirements in industrial device design and manufacturing.

www.phoenixcontact.com