www.ptreview.co.uk

08

'26

Written on Modified on

Laser Distance Sensing in Industrial Automation

Meskernal highlights how non-contact laser measurement supports precise positioning, real-time control, and reliable operation across automated manufacturing and material-handling environments.

meskernel.net

Laser distance sensing has become a core measurement technology in industrial automation, where accurate position and distance data directly influence machine control, robot guidance, and process monitoring. By measuring distances without physical contact, these sensors support high-throughput operations while reducing mechanical wear. The technology discussed here focuses on the role of laser distance sensors as a measurement and integration element within automated systems operating under demanding industrial conditions.

Why non-contact distance measurement is gaining ground

Modern automation systems increasingly require millimeter-level accuracy combined with fast response times to maintain stable control loops. Laser distance sensors meet these requirements by delivering high-resolution measurements without introducing mechanical interaction with the target. This makes them suitable for continuous operation in applications where contact-based methods would lead to wear, recalibration, or downtime. Their ability to operate at high sampling rates also supports real-time monitoring in tightly synchronized production lines, an important capability in data-driven industrial automation architectures.

Operating reliably in harsh industrial environments

Real-world factory conditions introduce challenges that directly affect measurement stability. Dust, moisture, vibration, and temperature variation can degrade sensor performance if not addressed at the design and integration stage. Industrial laser distance sensors are therefore typically specified with protection ratings such as IP54 or IP67, indicating resistance to particulate ingress and water exposure. Mechanical design and internal calibration mechanisms are also critical to prevent signal drift during continuous operation.

Ambient light and target reflectivity further complicate measurement. Sensors used in brightly lit environments or on surfaces with varying optical properties rely on optimized optics and signal processing to maintain accuracy. These design elements determine whether a sensor can deliver consistent data across different materials and lighting conditions without manual recalibration.

Integration constraints on the machine level

In many automated machines, available installation space is limited. Compact sensor housings and flexible mounting options simplify mechanical integration and reduce the need for custom brackets or enclosures. Electrical and data integration are equally important. To communicate reliably with PLCs and PACs, laser distance sensors often support standard industrial interfaces such as RS485, UART, Modbus, or industrial Ethernet. Compatibility with existing control architectures reduces commissioning time and minimizes the risk of communication bottlenecks.

Measuring distance: phase-based and time-of-flight approaches

Industrial laser distance sensors generally rely on either phase-based measurement or time-of-flight principles. Phase-based systems compare the phase shift between emitted and reflected light waves, making them well suited for short to medium ranges where high accuracy and fast sampling are required. These characteristics make them common in positioning tasks, closed-loop control, and material handling.

Time-of-flight sensors calculate distance by measuring how long a laser pulse takes to travel to a target and back. This approach supports longer measurement ranges, often several meters or more, and is frequently used in large-scale inspection, autonomous systems, and outdoor applications where extended reach is required. The choice between these principles depends on range, accuracy requirements, and system response time.

Automation use cases and measurable benefits

In conveyor systems, laser distance sensors mounted above the line continuously measure object height and position. This data enables dynamic control of spacing and sortation mechanisms, improving throughput consistency. In robotic assembly and palletizing, high-resolution distance feedback refines path accuracy, which can reduce cycle times and positioning errors. For bulk material handling, non-contact level measurement in bins and hoppers provides reliable inventory data even in dusty or reflective conditions, supporting more stable process control.

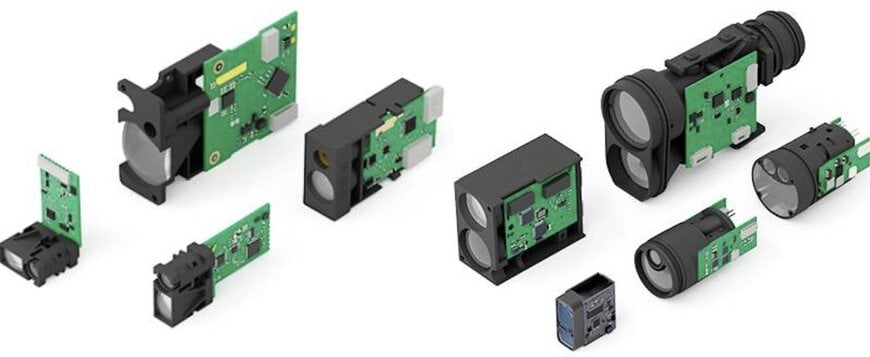

Selecting sensors for industrial projects

Choosing an appropriate laser distance sensor requires aligning measurement range and resolution with application needs while ensuring environmental suitability. Protection class, supported communication interfaces, and available mounting and power options all influence long-term system reliability. For embedded or OEM designs, modular sensor platforms with configurable optics, communication protocols, and mechanical interfaces can simplify integration into complex automation systems.

A measured role in modern automation

Laser distance sensing has established itself as a dependable measurement method within industrial automation, offering precise, non-contact data across a wide range of applications. When environmental factors, integration constraints, and measurement principles are properly accounted for, these sensors contribute to more stable control systems and more efficient automated operations without adding mechanical complexity.

www.meskernel.net