Quickparts Unveils “Quick Mould” Redefining Rapid Tooling with 5-Day Turnarounds Across Europe

This Bold New Service Offering Brings New Levels of Flexibility to Rapid Tooling, Streamlining Design, Tooling, Injection Moulding and Delivery.

quickparts.com

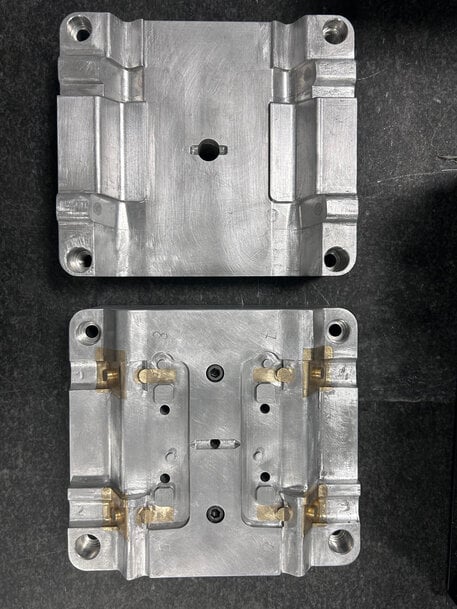

Case Study 1 - Tool

Celebrating its 35th anniversary as a trusted partner to manufacturers worldwide, Quickparts today announced the launch of Quick Mould, a cutting-edge rapid tooling solution designed to transform product development speed and flexibility for customers across Europe. Whether you’re iterating prototypes, validating a process, or gearing up for low-volume production, Quick Mould empowers designers and engineers to move from concept to fully functional, production-grade parts in record time.

“Quickparts was founded on the promise of Limitless Manufacturing, delivering high-quality parts without compromise on complexity, volume, or speed,” said Peter Jacobsen, EMEA President of Quickparts. “Quick Mould brings that philosophy to life, offering engineers a responsive, dependable solution to accelerate development, adapt to changes, and stay ahead of tight market deadlines.”

Why Quick Mould is a Gamechanger

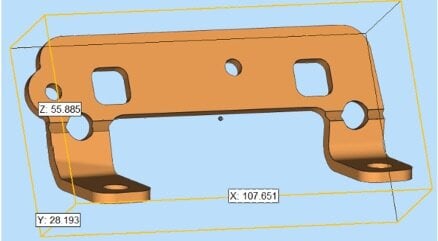

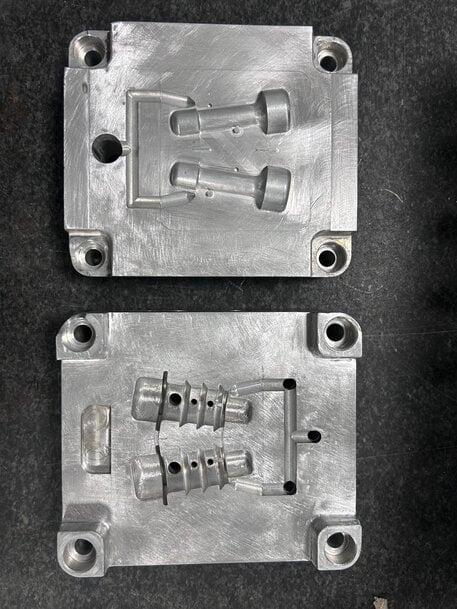

Backed by 35 years of technical expertise, Quick Mould combines rapidly machined aluminium moulds with high-performance thermoplastics to help customers:

- Iterate designs with exceptional agility

- Validate performance using real production materials

- Eliminate weeks of delay associated with traditional tooling

- Stay on schedule even with last-minute design changes

- Seamlessly scale up to full production using the same partner team

“Quick Mould gives our customers what they need most in today’s manufacturing landscape — time,” said Avi Reichental, CEO of Quickparts. “We recently demonstrated Quick Mould to leading industrial OEMs at our Pinerolo facility, and the response was outstanding. It’s a breakthrough that enables rapid decisions without sacrificing quality or reliability.”

Case Study 1 - CAD

Case Study 1 - Part

Proven Results, Delivered Fast

Quick Mould has already delivered value across a range of real-world applications:

- 1-day design change cycle completed using PA66 GF50

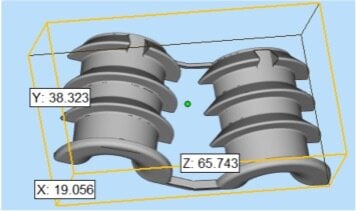

- 4-day turnaround on anti-vibration components for automotive use

- Last-minute door button redesign for a luxury vehicle, tooled and moulded in 4 days

- Bonding test rescue mission completed in 3 days with PA66 GF30 parts

Production is carried out locally at Quickparts’ European centre of excellence in Pinerolo, Italy, ensuring fast regional support and reduced logistics times.

Case Study 2 - CAD

Case Study 2 - Part

Case Study 2 - Tool

Quick Mould is now available across the EMEA region — the ideal solution for teams seeking speed, precision, and flexibility without compromise.

Visit the Quickparts website to learn more about Quick Mould and register for an exclusive webinar to walk through the technology, highlight case studies, and answer questions with subject matter experts.

www.quickparts.com/gb/