www.ptreview.co.uk

30

'25

Written on Modified on

SmartMeasure-AL: The next generation of automated industrial measurement

Mitutoyo’s innovative system revolutionizes industrial measurement processes by delivering precision, reliability, and full automation.

www.mitutoyo.com

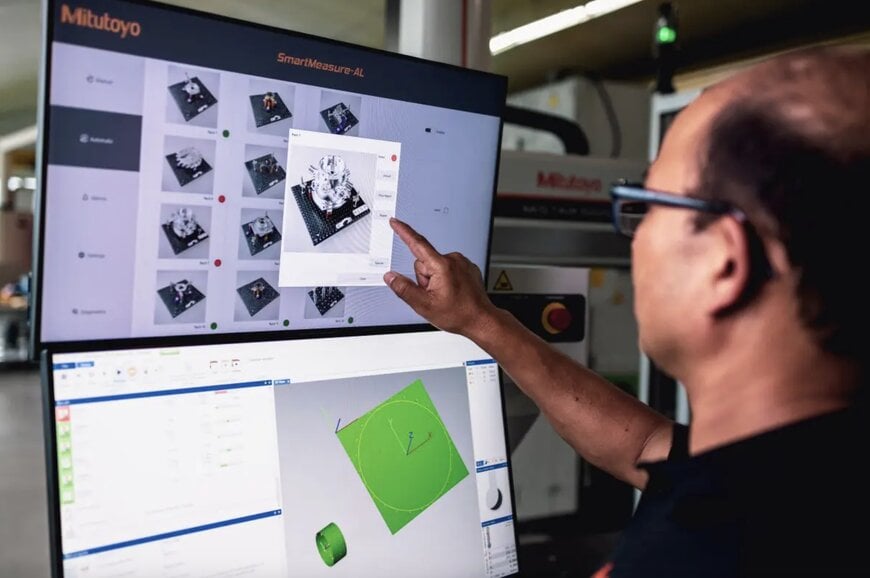

The SmartMeasure-AL is an advanced automated measurement system designed to operate seamlessly on Mitutoyo measuring machines. Featuring a pick-up rack, I/O station, storage system, system pallets, and a collaborative robot, it enhances efficiency and accuracy across various applications.

SmartMeasure-AL delivers high-precision measurement, 24/7, with no highly skilled operator required. This cutting-edge system integrates seamlessly into production lines, adapts to a variety of parts using RFID technology, and ensures consistent, high-quality results with zero downtime.

Designed for unattended, around-the-clock operation, SmartMeasure-AL is a plug-and-play solution that:

- automates quality assurance workflows,

- minimizes human intervention, and

- reduces labour dependency.

Key Features:

1. Efficient Measurement: The system allows for 24/7 automatic measurements, boosting efficiency and addressing manpower shortages. The operator simply needs to place the workpiece on up to 12 pallets, configure some measurement parameters, and let the system run autonomously.

2. Easy to Operate: With our Space4Win software and an easy and user-friendly GUI, an operator without knowledge of the system can easily run the whole setup.

3. Result Display: The measurement result is displayed via an indicator light on the HMI (green light for OK, red light for NOT OK).

4. Re-measure: With the help of the user-friendly software, the operator can easily re-measure parts that are NOT OK without having to run the whole sequence again.

5. Program Selection: The part program can be automatically selected by reading the RFID tag mounted on the pallet and by using the RFID reader mounted on the robot gripper.

6. Flexible Configuration: The combination of RFID tag and the part program can be modified simply by editing the settings file.

7. Connectivity: Once measurement is completed, measurement results can be sent to statistical software or even to external software. Moreover, results can be sent directly to CNC machines for tool correction with our Space4Win software.

SmartMeasure-AL was designed with a modular concept, as different customers have different requirements. Mitutoyo offers a base system, and based on specific requests or demands, the system can be configured accordingly. This modularity ensures that customers benefit from a flexible and customizable automated measurement solution.

Target Industries

SmartMeasure-AL is developed to handle a wide range of components across different industrial sectors, such as:

- Automotive

- Aerospace

- Medical

- Injection Moulding

- Energy

During a recent webinar, Pralhad Thapa, Manager – Business Solution Support Group, Mitutoyo Europe, shared key details about the SmartMeasure-AL system.

A unique automated measurement solution

While automated measurement solutions exist, Smart Measure-AL is unique. Developed as a full product with electronic integration, it delivers fast, cost-effective deployment. SmartMeasure AL is the only solution of its kind currently offered as a standardized, market-ready product.

Growing demand for in-line measurement

As the market is evolving, customer demands are shifting toward integrating measurement systems directly into production lines. In-line measurement enables faster feedback to CNC machines, allowing real-time process optimization. Mitutoyo supports this transition with a strong lineup of in-line measurement solutions.

Superior flexibility, traceability, and usability

SmartMeasure-AL is designed to be user-friendly, addressing the shortage of skilled operators with an intuitive graphical interface. It includes RFID technology for tracking parts and measurement data, enabling traceability and automatic remeasurement of defective parts. Delivered as a product, it offers high flexibility, performance, and pricing that outpaces comparable systems on the market.

Ease of use

SmartMeasure-AL uses Mitutoyo’s trusted Space4Win software, which is widely adopted by the European market. Customer feedback highlights its ease of use, which remains a key strength. Live demos show just how simple and intuitive the operation is.

Flexible robot and product integration

Although SmartMeasure-AL currently uses FANUC robots, the system is open to integrating other brands based on customer preferences. Mitutoyo also plans to expand SmartMeasure-AL for use with other systems, supporting broader factory automation goals.

Supporting sustainable manufacturing

SmartMeasure-AL features a compact footprint and low power consumption. As a fully automated system capable of running unattended overnight, it minimizes energy usage related to operator presence and lighting.

Flexible pallet and fixture use

Built on a modular concept, SmartMeasure-AL adapts to various customer needs. While the base remains standardized, the system accommodates different pallet sizes and fixturing methods, offering the flexibility required for diverse applications.

A unique automated measurement solution

While automated measurement solutions exist, Smart Measure-AL is unique. Developed as a full product with electronic integration, it delivers fast, cost-effective deployment. SmartMeasure AL is the only solution of its kind currently offered as a standardized, market-ready product.

Growing demand for in-line measurement

As the market is evolving, customer demands are shifting toward integrating measurement systems directly into production lines. In-line measurement enables faster feedback to CNC machines, allowing real-time process optimization. Mitutoyo supports this transition with a strong lineup of in-line measurement solutions.

Superior flexibility, traceability, and usability

SmartMeasure-AL is designed to be user-friendly, addressing the shortage of skilled operators with an intuitive graphical interface. It includes RFID technology for tracking parts and measurement data, enabling traceability and automatic remeasurement of defective parts. Delivered as a product, it offers high flexibility, performance, and pricing that outpaces comparable systems on the market.

Ease of use

SmartMeasure-AL uses Mitutoyo’s trusted Space4Win software, which is widely adopted by the European market. Customer feedback highlights its ease of use, which remains a key strength. Live demos show just how simple and intuitive the operation is.

Flexible robot and product integration

Although SmartMeasure-AL currently uses FANUC robots, the system is open to integrating other brands based on customer preferences. Mitutoyo also plans to expand SmartMeasure-AL for use with other systems, supporting broader factory automation goals.

Supporting sustainable manufacturing

SmartMeasure-AL features a compact footprint and low power consumption. As a fully automated system capable of running unattended overnight, it minimizes energy usage related to operator presence and lighting.

Flexible pallet and fixture use

Built on a modular concept, SmartMeasure-AL adapts to various customer needs. While the base remains standardized, the system accommodates different pallet sizes and fixturing methods, offering the flexibility required for diverse applications.