www.ptreview.co.uk

30

'25

Written on Modified on

ABB expands large industrial robot portfolio

ABB expands industrial robot portfolio with IRB 6730S, 6750S, and 6760, delivering superior performance, sustainability, and broad application versatility.

global.abb

IRB 6750S high-performance space-optimized shelf robots

ABB Robotics is expanding its large robot portfolio with the launch of the IRB 6730S, IRB 6750S and IRB 6760. The introduction of these new robots, alongside the wider portfolio of next generation robots launched since 2022, now means the company can offer its customers the most comprehensive lineup of industrial robots and variants on the market. The lineup of 11 next generation robot families comprising 60 variants offers customers new levels of flexibility and choice as well as class-leading performance and sustainability benefits.

IRB 6750S shelf robots offer class-leading payloads of up to 350kg

IRB 6750S shelf robots offer class-leading performance

“The launch of our new robots supports our vision that ‘versatility' will be the defining factor for robotics in 2025,” said Marc Segura, President - Robotics Division at ABB. “This market-leading range of industrial robots and variants, coupled with our comprehensive portfolio of mechatronic platforms, cobots, and AMRs, ensures we are ideally placed to support our customers as we enter a new world of increased productivity and flexibility. And our automation solutions can help companies to address challenges such as labor shortages while supporting sustainable operations.”

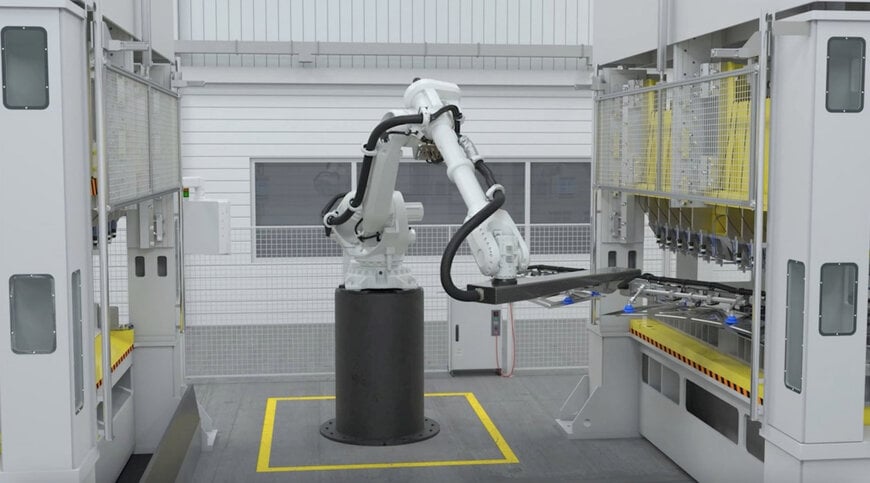

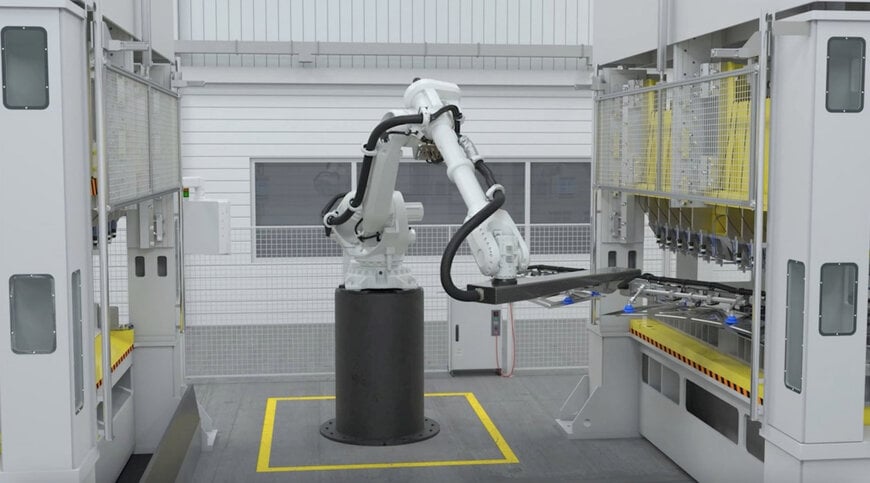

IRB 6730S shelf robots are designed for die casting

The IRB 6730S and IRB 6750S are both shelf-mounted robots and have been designed to support an increase in robot density in the production line. Capable of handling industry-leading payloads of up to 350 kg, the shelf robots can be installed at a height (or on a second floor) and can work with floor-mounted robots to maximize productivity. In addition, the robots provide excellent full vertical and horizontal motion to increase downward reach, making them ideal to optimize the space for die casting, injection molding, and spot welding for use in automotive, foundry, construction, and general manufacturing industries.

IRB 6750S shelf robots are designed for Giga press

High-performing large robot family 60 variants

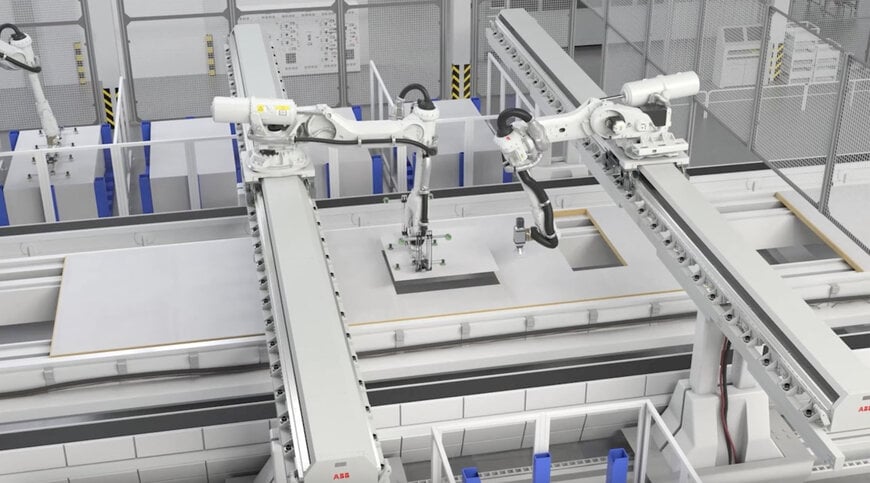

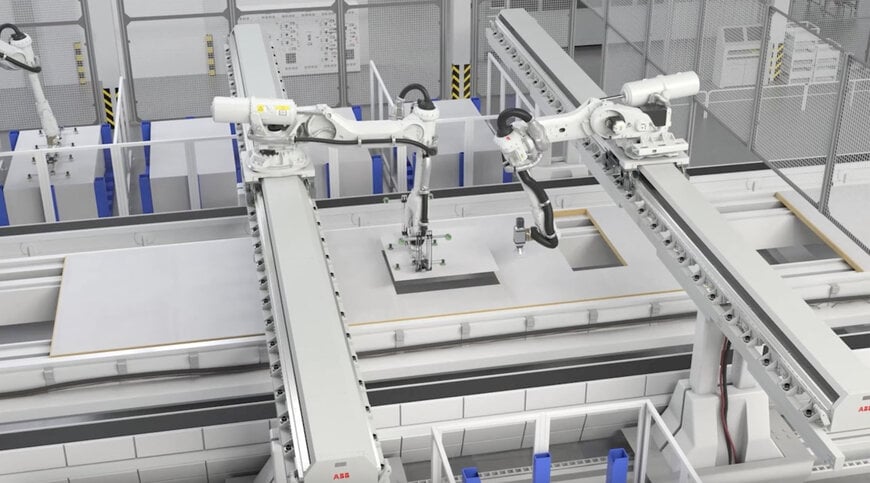

The new IRB 6760, a member of ABB’s latest generation of press tending robots, is the highest performance solution to date for mid-sized press lines. When combined with ABB’s carbon-fiber tooling boom, it can boost production output to a market-leading rate of up to 15 strokes per minute or 900 parts per hour. The IRB 6760 press tending robot is recommended for automotive, electronics and general manufacturing industries.

IRB 6730S IRB 6750S IRB 6760

IRB 6760 press tending robot offers up to 15 SPM to produce 900 parts per hour

All three new robots are powered by OmniCoreTM, ABB’s advanced controllers for automation, delivering a 20% reduction1 in energy consumption and class-leading performance. For example, the IRB 6750S in conjunction with an OmniCoreTM controller can deliver path accuracy down to 0.9 mm.

IRB 67XOS shelf robots are ideal for material handling and cutting in construction

IRB 6730S offer up to 80 spot welds in just 15 seconds

The comprehensive lineup of next generation robots has been launched to work in partnership to further optimize plant performance. For example, ten IRB 6730S or IRB 6750S shelf-mounted robots can work in unison with eight floor-mounted IRB 6710~IRB 6740 robots to increase the number of spot welds on a car body from 70 to 80 joints in just 15 seconds, compared to predecessors. In addition, the groundbreaking modular design of the lineup can help reduce total cost of ownership through shared spare parts and service tools.

1 Power consumption: IRB 6750S compared with IRB 6650S-200/3.0 running on IRC5

www.abb.com

ABB Robotics is expanding its large robot portfolio with the launch of the IRB 6730S, IRB 6750S and IRB 6760. The introduction of these new robots, alongside the wider portfolio of next generation robots launched since 2022, now means the company can offer its customers the most comprehensive lineup of industrial robots and variants on the market. The lineup of 11 next generation robot families comprising 60 variants offers customers new levels of flexibility and choice as well as class-leading performance and sustainability benefits.

IRB 6750S shelf robots offer class-leading payloads of up to 350kg

IRB 6750S shelf robots offer class-leading performance

“The launch of our new robots supports our vision that ‘versatility' will be the defining factor for robotics in 2025,” said Marc Segura, President - Robotics Division at ABB. “This market-leading range of industrial robots and variants, coupled with our comprehensive portfolio of mechatronic platforms, cobots, and AMRs, ensures we are ideally placed to support our customers as we enter a new world of increased productivity and flexibility. And our automation solutions can help companies to address challenges such as labor shortages while supporting sustainable operations.”

IRB 6730S shelf robots are designed for die casting

The IRB 6730S and IRB 6750S are both shelf-mounted robots and have been designed to support an increase in robot density in the production line. Capable of handling industry-leading payloads of up to 350 kg, the shelf robots can be installed at a height (or on a second floor) and can work with floor-mounted robots to maximize productivity. In addition, the robots provide excellent full vertical and horizontal motion to increase downward reach, making them ideal to optimize the space for die casting, injection molding, and spot welding for use in automotive, foundry, construction, and general manufacturing industries.

IRB 6750S shelf robots are designed for Giga press

High-performing large robot family 60 variants

The new IRB 6760, a member of ABB’s latest generation of press tending robots, is the highest performance solution to date for mid-sized press lines. When combined with ABB’s carbon-fiber tooling boom, it can boost production output to a market-leading rate of up to 15 strokes per minute or 900 parts per hour. The IRB 6760 press tending robot is recommended for automotive, electronics and general manufacturing industries.

IRB 6730S IRB 6750S IRB 6760

IRB 6760 press tending robot offers up to 15 SPM to produce 900 parts per hour

All three new robots are powered by OmniCoreTM, ABB’s advanced controllers for automation, delivering a 20% reduction1 in energy consumption and class-leading performance. For example, the IRB 6750S in conjunction with an OmniCoreTM controller can deliver path accuracy down to 0.9 mm.

IRB 67XOS shelf robots are ideal for material handling and cutting in construction

IRB 6730S offer up to 80 spot welds in just 15 seconds

The comprehensive lineup of next generation robots has been launched to work in partnership to further optimize plant performance. For example, ten IRB 6730S or IRB 6750S shelf-mounted robots can work in unison with eight floor-mounted IRB 6710~IRB 6740 robots to increase the number of spot welds on a car body from 70 to 80 joints in just 15 seconds, compared to predecessors. In addition, the groundbreaking modular design of the lineup can help reduce total cost of ownership through shared spare parts and service tools.

1 Power consumption: IRB 6750S compared with IRB 6650S-200/3.0 running on IRC5

www.abb.com