www.ptreview.co.uk

16

'21

Written on Modified on

Complete surface inspection with 3D smart sensors

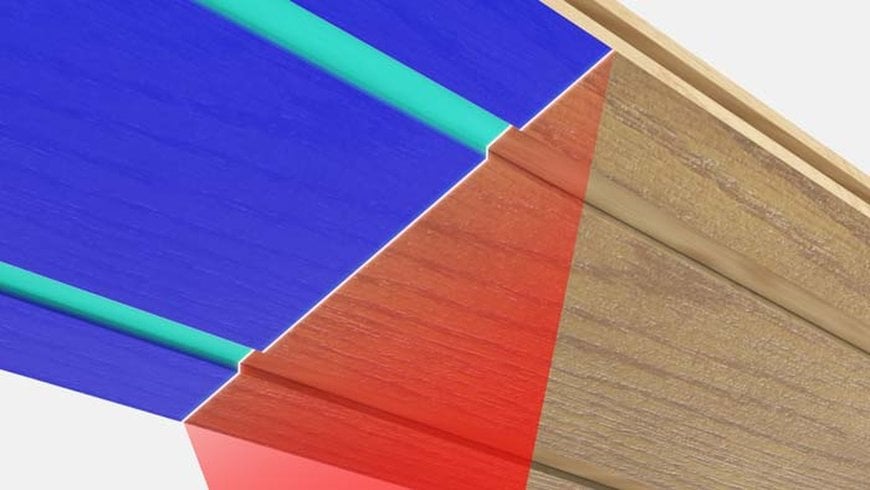

Wood panel scanning using a mixed model sensor system.

Surface inspection can be a highly complex task especially with product shapes such as wood flooring panels where you need to inspect both large areas of the panel surface finish at the same time as detailed high-resolution profile of the tongue and groove sides.

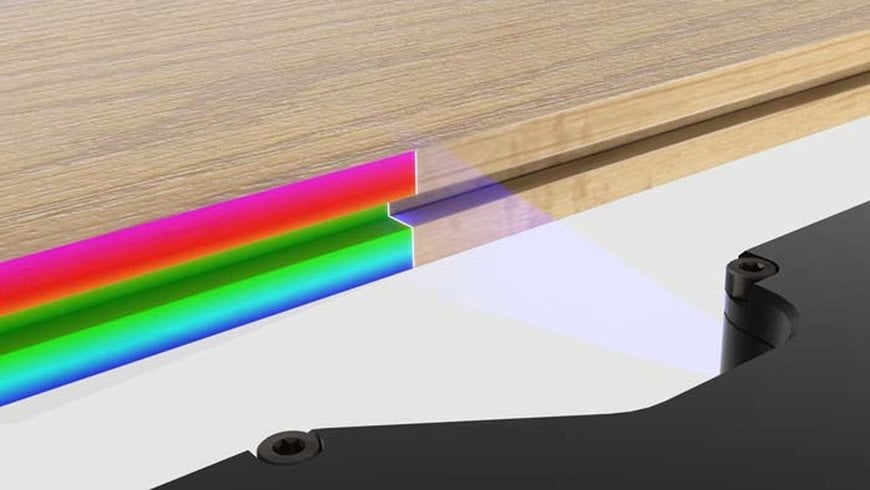

This article explains how to master this challenge in a single work step. By combining different LMI 3D laser line profilers into a single system allows you to scan large areas and at the same time capture the smallest details in high resolution.

LMI Gocator now supports mixed multi sensor networking, allowing users to mix and match sensors from the same series. Here we explore an example of scanning a floorboard, where half of the inspection task requires fine feature measurement, and the other half requires a large FOV.

The eternal dilemma: field of view or resolution?

3D inspection systems combining multiple laser line profilers are typically limited to using sensors of the same model type.

This solution makes perfect sense, when you need to extend the field of view while maintaining the same measurement resolution, however, what happens if the application requires simultaneous inspection of fine details and large areas?

The LMI Gocator 2420 is the higher resolution model in the series and is therefore able to generate the required high-precision 3D data from the panel’s tongue and groove edges.

These “dual requirement” applications cannot be solved using just one sensor model alone without making a compromise on either resolution or field of view. Sensor models that have wide fields of view typically have lower resolution, and sensor models with high resolution typically have much smaller fields of view.

What you really need to solve the application is the ability to network two different sensor models into one system using a combined co-ordinate system.

Combining different 3D laser sensors for complete single pass inspection

With LMI Gocator 3D line profilers we can now combine different models from the same series into a single system, taking advantage of the higher resolution of one model (such as LMI Gocator 2510) and the wider field of view of another (such as LMI Gocator 2530).

Mixed model networking capability allows you to perform a high-resolution inspection only on areas where it is needed (that is, where there are fine features), while simultaneously getting wide overall coverage from other sensors in the network in order to capture the entire object surface.

Application example

Inspecting wood panels using a mixed model LMI Gocator sensor system

The inspection of wooden floor panels requires various types of information: The panels have to be scanned and measured for complete dimensions, while the panel’s tongue and groove edges must be inspected for fine features and tight dimensional tolerances.

To solve this challenge a mixed model multi-sensor system can be created that leverages two large field of view laser profiler models (LMI Gocator 2440) and two high resolution models (LMI Gocator 2420).

In summary, this unique type of multi-sensor system allows users to achieve fine-feature inspection on a specific region of interest (ROI), while simultaneously achieving wide surface coverage. The result is an inspection system built on the fewest number of sensors and the lowest possible total system cost.

www.stemmer-imaging.com