EMO PRE-SHOW PRESS RELEASE

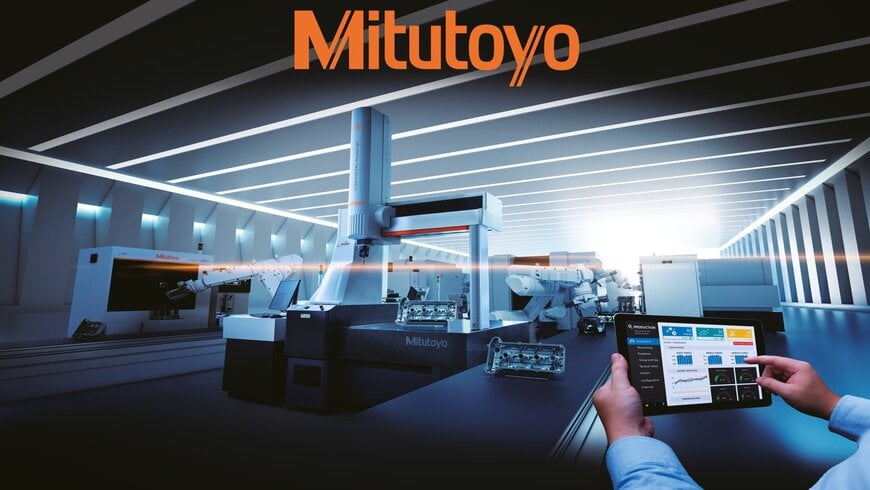

Mitutoyo to Showcase Cutting-Edge Metrology Solutions at EMO 2025 in Hannover Next-Gen Measurement for Next-Level Manufacturing.

www.mitutoyo.eu

Neuss, Germany – July 2025 – Mitutoyo, the global leader in precision measuring instruments and metrology solutions, is excited to announce its participation at the EMO International Trade Fair for Quality Assurance in Hannover, Germany, taking place from 22 to 26 September 2025.

Visitors will find Mitutoyo at Hall 5 – Stand C44, where the company will present its latest innovations in coordinate measuring machines (CMMs), form measuring equipment, vision measurement systems, digital solutions tailored for Industry 4.0 and smart manufacturing environments. Live demonstrations and expert consultations will be available throughout the exhibition.

“EMO is one of the most important industry events for quality assurance, and we’re excited to demonstrate how Mitutoyo continues to lead the way in precision, automation, and digital transformation,” said Ray Penny, President at Mitutoyo Europe. “At Mitutoyo, our mission is to enable manufacturers to move forward with confidence, powered by intelligent, agile, and integrated metrology solutions.”

Throughout the exhibition, Mitutoyo’s specialists will be on-site to provide live demonstrations, technical insights, and one-on-one consultations, helping visitors discover how integrated metrology can improve productivity, reduce error, and elevate quality assurance across industries.

Join us at Stand C44 in Hall 5 and discover the future of precision measurement. Mitutoyo, From Microns to Mastery: Precision You Can Trust. Because Precision is in our DNA

Figure 1 - Discover Mitutoyo's SmartMeasure-AL system – a seamless integration of coordinate measurement and robotic intelligence. A key step toward future-ready manufacturing.

Figure 2 - At the heart of tomorrow’s smart factory, the CRYSTA-Apex from Mitutoyo delivers unmatched precision and highly accurate measurements at high speed. From inline measurement to automated control, we’re shaping the future of manufacturing.

Figure 3 - Unlock microscopic precision at incredible speeds. A breakthrough in high-speed, all-in-focus imaging using tunable acoustic gradient-index lens technology. Perfect for dynamic, real-time 3D observation.