Universal Robots Shows Deep Learning-Based Part Detection

The pioneer of collaborative robotics is set to unveil a new AI-powered machine tending solution at IMTS, advanced cobot applications for welding, finishing, part feeding, and laser marking.

www.universal-robots.com

When Universal Robots (UR) recently surveyed 1,200 manufacturers across North America and Europe about their use of technology and future investment plans, over 50% of the respondents indicated they are now using AI and machine learning in their production processes.

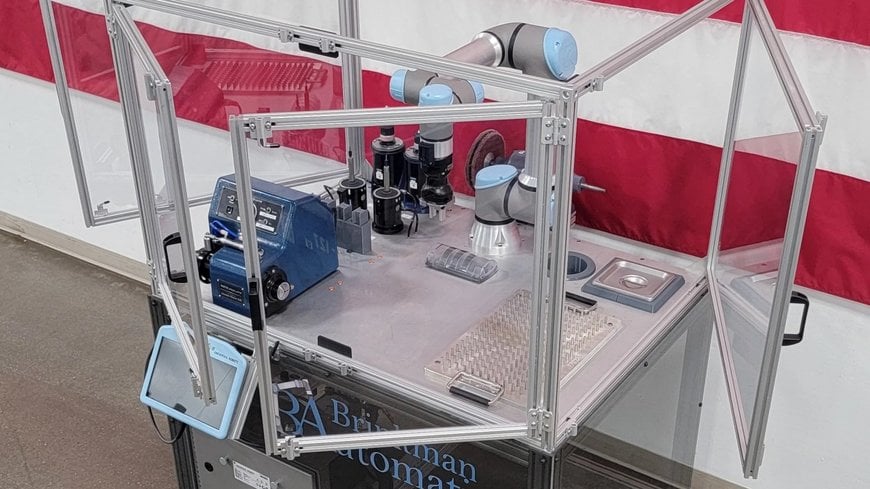

At UR’s IMTS booth #N 236131, September 9-14 in Chicago, the company will show a machine-tending application with new AI-based perception capabilities running on NVIDIA Jetson and Isaac acceleration libraries integrated into UR’s new PolyScope X platform. This combination enables dynamic path planning, ensuring the robot takes the most effective, collision-free paths in and out of the machine without requiring extensive user configuration. UR plans to make this cutting-edge technology available for a wide range of applications, including machine tending and other material handling tasks.

An important production parameter is cobot uptime. To ensure seamless operations and increased efficiency, UR has launched the enhanced UR Care Service Plans that now offer preventive field service, onsite break-fix, dedicated remote support and secure cloud connectivity-based cobot service/performance monitoring through UR Connect, showcased for the first time at IMTS.

Unlike other service and repair offerings that often involve numerous platforms, channels, and logins, UR now provides all service, support, and training through the fleet management portal myUR.

www.universal-robots.com