www.ptreview.co.uk

23

'25

Written on Modified on

PlastiVation relies on KEBA's CRA-compliant remote maintenance solution

KEBA RemoteConnectivity as used by PlastiVation demonstrates very well how the Kemro X platform modules integrate seamlessly into a KePlast application for plastics machines or custom OEM solutions.

www.keba.com

How can service be designed digitally while remaining human and trustworthy? PlastiVation demonstrates how companies can differentiate themselves in service, support customers efficiently, and sustainably reduce costs with our remote access solutions – all in compliance with the Cyber Resilience Act (CRA), in effect since December 2024, which sets new standards for remote machine access by 2027.

From start-up to European innovation center

Founded in 2021, PlastiVation Machinery GmbH, the German subsidiary of Tederic Machinery Co., Ltd., has quickly grown from a start-up and sales agency for Tederic into an end-to-end solution provider with an excellent reputation in the market. In addition, the company is Tederic’s European R&D center. If offers a broad range of value-for-money, energy-efficient, reliable injection molding machines in Tederic’s NEO series as well as turnkey production cells that also include robots and peripherals. As part of Tederic’s global development team, PlastiVation is a driver of product innovation and adapts existing solutions to the needs of European customers.

In this, we act as a strategic technology partner and provides the KePlast control system which forms the basis for the automation of Tederic’s injection molding machines. Since its foundation, we have also been supporting PlastiVation with solutions for closed-loop control engineering, digitization and interface integration (e.g. OPC UA, EUROMAP 82).

Dr. Daniel Ammer, PlastiVation VP for R&D, emphasizes: “In Europe, we are faced with economic and geopolitical challenges, and the market situation for injection molding machines is currently far from easy. Our strong focus on customer service and digital tools puts us on the right path. KEBA's solid reputation in the industry and its well-known solutions for machine operators are a significant benefit for us.” Günther Weilguny, Head of Automation Plastics at KEBA, also looks back on the good success of this cooperation so far. “We are connected by our shared enthusiasm for technology and our interactions as equal partners—on both sides. We start at the customer’s pain point and think things through until we arrive at the solution”, says Günther Weilguny.

Differentiation through excellent service

PlastiVation wanted to clearly distinguish themselves from conventional machine suppliers. Their approach: to act as customer-oriented solution provider who supports its customers at a personal level during the entire product life cycle—from installation to training to ongoing support, well beyond the simple delivery of the product. The market situation as well as trends such as teleworking and global teamwork required new models for customer service. It quickly emerged that customer service must be digital, CRA-compliant and available in real time in order to guarantee maximum machine productivity for customers.

Asked whether customer support is possible entirely without actual personal contact, Mr. Ammer replies: “Personal contact is important during the sales and after-sales stages, but when a machine stops for any reason at all and support is needed, every minute counts. This is the very situation where our customers can remotely reach an actual human who can help.”

Preventing machine downtime, speeding up service turnaround times and optimizing the availability of technical experts—all of these were at the top of the list of pain points. A particular focus was on keeping the associated costs down as much as possible. These costs can vary widely, depending on the number of technicians, the travel destination and the production needs, and they can quickly climb from several thousand to tens of thousands of euros per day.

One of the biggest hurdles, however, was to build confidence in digital tools, in particular with a view to data protection and cybersecurity. “Many customers have made the experience that new technologies don't always live up to what they’ve promised. But as soon as it becomes evident that a solution is secure and reliable, the demand for scalability follows,” explains Dr. Maximilian Wank, Lead Digital Solutions Architect at PlastiVation. “This is why we are happy about every installation, as it provides us with that valuable feedback that we are a reliable, secure choice as machine supplier and partner. This is a great proof of confidence,” adds Mr. Ammer.

And this is how we became the solution of choice: “We are already using KEBA control systems, and when we needed a user-friendly solution that would be quick to implement and we wanted to remain open for the integration of future KEBA functionality, KEBA ServiceNet emerged as the best option for our purposes,” says Mr. Ammer.

CRA-compliant KEBA ServiceNet

KEBA ServiceNet is a plug-and-play support package based on KEBA RemoteConnectivity, an IEC62443-compliant remote maintenance solution. It is part of the Kemro X automation platform. KEBA ServiceNet integrated seamlessly into the machine operations at PlastiVation. It has been optimized for temporary access whenever support is needed. In such a case, the solution provides a private network connection, allowing the customer to receive immediate assistance.

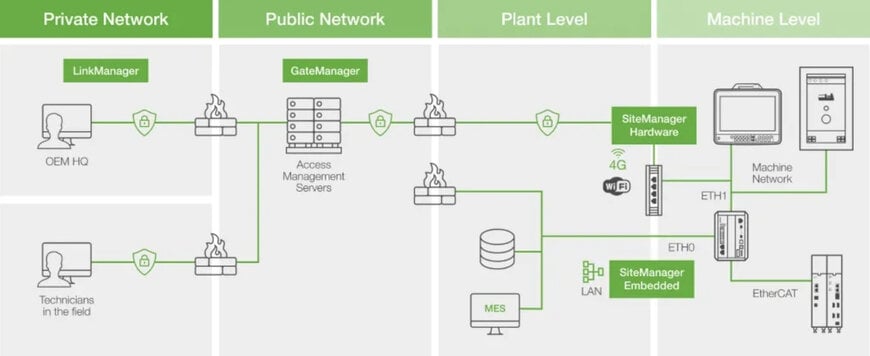

The underlying RemoteConnectivity package rests on three pillars: SiteManager as LTE/WIFI/LAN device, LinkManager for client access on the service PC, and GateManager as control room in the cloud. With servers in Hong Kong and Denmark, it covers all requirements regarding worldwide secure connections.

The example of KEBA RemoteConnectivity as used by PlastiVation demonstrates very well how the Kemro X platform modules integrate seamlessly into a KePlast application for plastics machines or custom OEM solutions.

Three pillars of KEBA RemoteConnectivity

Typical use cases of KEBA ServiceNet

Three typical use cases at PlastiVation demonstrate the practical benefits:

1. Optimizing customer service operations: Service technicians obtain direct access to the machines on site while experts at the central office provide assistance ranging from diagnostics to software updates. This provides for significantly faster response times and saves on travel expenses.

2. Improving customer support: Customers can avail themselves, directly and remotely, of support provided by application engineering experts whenever they have questions regarding machine operation or process optimization, such as the prototyping of new injection-molded parts, issues with rejects, or quality concerns. This increases production efficiency and reduces downtime significantly. Instead of having to wait for hours or days for an available technical expert to come on site, help arrives in mere minutes.

3. R&D teamwork: Developers and engineers at the Tederic headquarters in China or PlastiVation engineers working from home have secure access to the machines, allowing research and development teams to collaborate efficiently across multiple locations.

The background knowledge of building on top of a secure and certified solution creates a solid foundation for the future. The CRA-compliance of the KEBA RemoteConnectivity products strengthens the customers’ confidence in this solution. Customers are in control of the connection and have easy means of deciding when and for how long a remote session with an expert via the internet will be held. After the remote access has ended, the machine resumes operation inside the customer’s secure OT network, minimizing the risk of cyberattacks.

In some cases, however, other solutions from our digitization portfolio are the better choice. For a use case with continuous production monitoring, for example, we recommend using an MES system via the standardized EUROMAP 77 interface.

ROI in record time

After a quick and easy installation that did not require any training, the benefits were soon felt. Less travel, quicker assistance, greater customer satisfaction. Typically, the return on investment becomes measurable after just a few days.

Mr. Wank describes the practical benefits: “By using KEBA solutions, we are able to support customers who have issues with their processes directly via remote access to the machine control system without the need for an on-site visit by process experts. This reduces the high travel expenses, which amount to roughly 1000 euros within Germany and can easily rise to as much as 2500 to 3000 euros per day for trips abroad. Quite often, the solution pays for itself within just one week because expensive on-site visits are no longer necessary and machine availability improves. Many customers appreciate this convenience and the quick response times.”

One satisfied end customer is Mr. Markus Kremers, Managing Director at Formzeug GmbH & Co. KG, who confirms: “We are particularly impressed with the KEBA RemoteConnectivity maintenance system with the ServiceNet package. It helps our set-up and maintenance staff to optimize processes and increase production efficiency. Consequently, we experience less machine downtime and improve the quality of our work.”

Outlook: Next steps in digitization

The future cooperation will continue to center on digitization solutions and the further evolution of process control with KePlast technologies, for example axis controllers for the compensation of material characteristics. Technologies such as artificial intelligence and self-learning algorithms will play an ever greater role. In addition, the introduction of new HMI technologies and the implementation of further EUROMAP interface standards for peripherals will be the subject of further developments.

www.keba.com